Six Sigma Green Belt professional is a skilled team player who improves process quality. They use their knowledge of the methodology in real-life organizational situations and help to improve various aspects of work processes that include project processes, data inspection, and general processes.

Responsibilities of Green Belt Professional

- Six Sigma Green Belt Professional have skills and knowledge on the Six Sigma improvement methodology that lead a process improvement team.

- With having a deeper understanding of the overall process, they lead ‘Six Sigma improvement’ project’s team.

- Green belts operate under the supervision of a Six Sigma Black Belt. Moreover, they analyzes and solves quality problems.

- They coordinate with the data collection process team of their project and validate the measurement system

- They usually work on projects within their own functional area and also improve their team facilitation skills.

Six Sigma Green Belt Career Opportunities

Indeed learning Six Sigma methodologies will help better your career and available opportunities. Moreover, your commitment to go for a Six Sigma Certification to your profile proves your commitment towards improving your business acumen, analytical skills, and work output. Let us now look in detail of the Six Sigma Green Belt Career Opportunities.

Vskills Certified Six Green Belts Professional: Overview

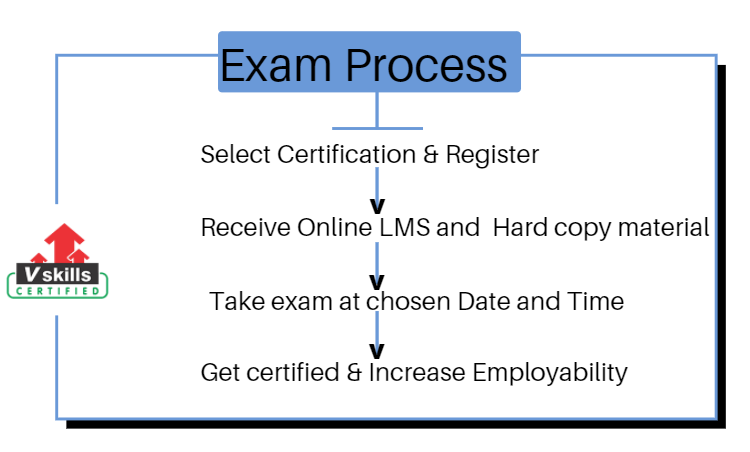

Vskills Six Sigma Green Belt Professional certification measures the candidate according to the company’s need for deploying, managing, and maintaining quality systems. The certification will examine the candidate’s skills and knowledge in various areas that will cover lean and six sigma principles, DMEA, QFD, collecting and summarizing data, statistical analysis, and process control.

Certification Benefits

Getting certified with Six Sigma Green Belt Professional will help candidates to prepare a career in Quality Control. Moreover, this will help candidates to stand in today’s competitive job market by advancing their skills for getting employment opportunities. Green Belts Professionals are considerably valuable to a company for their functional knowledge and expertise in improving the processes.

Vskills being India’s largest certification providers gives candidates access to top exams as well as provides after exam benefits. This includes:

- The certifications will have a Government verification tag.

- The Certification is valid for life.

- Candidates will get lifelong e-learning access.

- Access to free Practice Tests.

- Candidates will get tagged as ‘Vskills Certified’ On Monsterindia.com and ‘Vskills Certified’ On Shine Shine.com.

Test Details

- Exam Duration: 60 minutes

- Vskills Exam Code: VS-1103

- Number of questions: 50

- Maximum marks: 50

- Passing marks: 25 (50%).

- There is NO negative marking in this module.

Course Outline for Certified Six Green Belts Professional

Certified Six Green Belts Professional covers the following topics –

Six Sigma and Organization Goals

Define Phase

- Introduction to Define Phase

- Business Process

- Project Identification

- Voice of Customer (VOC)

- CTx (Critical to x) Requirements

- Project Management

- Management and Planning Tools

- Business Results for Projects

- Team Dynamics and Performance

Measure Phase

- Introduction to Measure phase

- Process Analysis and Documentation

- Statistics and Probability

- Data Types, Collection and Accuracy

- Graphical Summarization

- Probability Distributions

- Measurement System Analysis

- Control Chart

- Process Capability and Performance

Analyze Phase

Improve Phase

Control Phase

Other References

Six Sigma and Organization

Six Sigma and Organizational Goal

Lean Principles

Design for Six Sigma (DFSS)

Define

Process Management

Project Management

Management and Planning Tools

Team Dynamics and Performance

Measure

Process Analysis and Documentation

Statistics and Probability

Collecting and Summarizing Data

Probability Distributions

Measurement System Analysis

Control Chart

Process Capability and Performance

Analyze

Exploratory Data Analysis

Hypothesis Testing

Improve and Control

Design of Experiments (DOE)

Statistical Process Control (SPC)

Implement and Validate

Control Plan

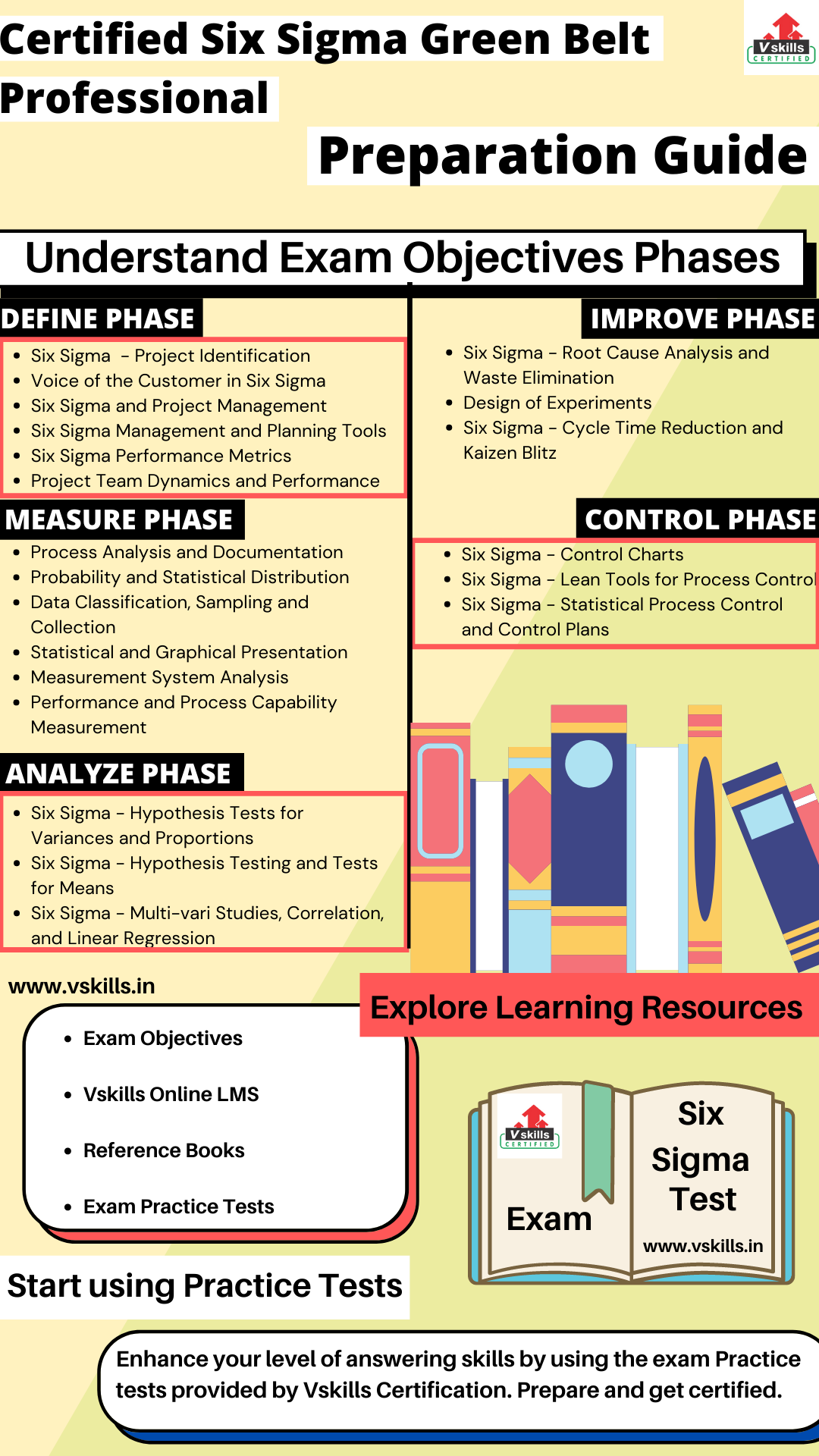

Preparation Guide for Vskills Certified Six Green Belts Professional

Candidates preparing for the exam should understand the importance of exam resources. During the exam preparation, it is essential to get all the required exam study resources. This will provide an advantage to understand the concepts and meaning more accurately. In the Certified Six Green Belts Professional preparation guide, we will discuss some of the most important resources to help you prepare well for the exam.

Study Resource: Exam Objectives

For every examination, the first task should be to get all the exam related details including the important contents and its topic. This will help candidates to easily start preparing for the exam and to understand things more accurately. For the Certified Six Green Belts Professional exam, the topics include:

DEFINE PHASE

- Six Sigma – Project Identification

- Voice of the Customer in Six Sigma

- Six Sigma and Project Management

- Six Sigma Management and Planning Tools

- Six Sigma Performance Metrics

- Project Team Dynamics and Performance

MEASURE PHASE

- Process Analysis and Documentation

- Probability and Statistical Distribution

- Data Classification, Sampling and Collection

- Statistical and Graphical Presentation

- Measurement System Analysis

- Performance and Process Capability Measurement

ANALYZE PHASE

- Six Sigma – Hypothesis Tests for Variances and Proportions

- Six Sigma – Hypothesis Testing and Tests for Means

- Six Sigma – Multi-vari Studies, Correlation, and Linear Regression

IMPROVE PHASE

- Six Sigma – Root Cause Analysis and Waste Elimination

- Design of Experiments

- Six Sigma – Cycle Time Reduction and Kaizen Blitz

CONTROL PHASE

- Six Sigma – Control Charts

- Six Sigma – Lean Tools for Process Control

- Six Sigma – Statistical Process Control and Control Plans

Study Resource: Vskills Online LMS

Vskills Certified Six Green Belts Professional provides candidates access to prepare for the exam using the online learning material for a lifetime. The online material for this is regularly updated. Furthermore, e-learning is bundled with hard copy material which helps candidates to improve and update the learning curve for superior and better opportunities.

Study Resource: Books for Reference

Reference Books can provide an advantage to learn and understand things more accurately. For the Certified Six Green Belts Professional exam, there are various books available which you can find online or in libraries. Some of the books are as follows:

- Six Sigma Green Belt Certification Project by Reiner Hutwelke

- Six Sigma for Green Belts and Champions by Howard S. Gitlow

Study Resource: Practice Test

After understanding and learning about the Certified Six Green Belts Professional topics, it is time for practice tests. That is to say, practice tests are important for better preparation as by assessing yourself with these tests you will know about your weak and strong areas. Moreover, you improve your answering skills for getting better results. So, make sure to find the best practice sources.

Six Sigma Green Belt Interview Questions

Get ready to crack interview with our latest expert created interview questions, the questions are meant for beginners, professionals and experts. The main purpose of these questions is to prepare for the job interviews.