Certification have always been the most lucrative option to advance the career. They help you to develop you in professional terms and level up in your career. And who does not want to achieve a higher post and higher salary! Certifications not only help you climb the corporate ladder but also are financially rewarding. In other words, certifications have become the global currency of 21st century to secure a real job.

Moreover, certifications like Six Sigma Green Belt hold some real value in job market and helps you to progressively move forward in your career, both financially and by designation. The domain of business management really demands professional with the skills that the certification develops in the candidates. This will help you to prove your commitment to improving your business acumen and analytical skills, as well as improving the business where you work. Let us dive deeper into knowing what is the use of taking the Six Sigma Green Belt certification and how taking the certification can prove to be beneficial for your career.

About Six Sigma Green Belt certification

A Certified Six Sigma Green Belt is an individual that possesses a thorough understanding of enhanced problem-solving skills, with an emphasis on the DMAIC (Define, Measure, Analyze, Improve and Control) and QFD model.

Certification for Six Sigma – Green Belt Professional assesses the candidate as per the company’s need for deploying, managing and maintaining quality systems. The certification tests the candidates on various areas in lean and six sigma principles, DMEA, QFD, collecting and summarizing data, statistical analysis and process control. Let us now have a look at the concepts that will be covered in the certification.

Target audience

The six sigma green belt certification is designed for a career in quality control or the allied roles in managing the quality. Therefore, this certification is designed especially for the job seekers looking to set their foot in the quality control sector. There is no specific prerequisite for taking the certification, so anyone interested in the domain can take the certification. However, any experience in this domain could help you easily understand the concepts involved in the certification exam.

Concept covered in Six Sigma Green Belt

The scope of this certification is very wide. However, The list of topics across D-M-A-I-C framework, that are normally covered in Six Sigma Green Belt are as follows:

- Firstly, learn about Change Management

- Understand KANO Model, SIPOC diagram

- Learn about Process capability, Segmentation and Stratification, Sampling strategy

- Subsequently, learn about Measurement System Analysis, Project charter, Voice Of the Customer (VOC) to Critical-To-Quality (CTQ)

- Then understanding Box Plot, Process Map

- Learn about Pareto, Concept of LEAN, Hypothesis Testing, Rolled Throughput Yield (RTY)

- Subsequently, Correlation, Mistake-proofing, FMEA

- In addition, Fishbone Diagram, Normality study, Statistical Process Control (SPC)

- moreover, Process Management Charts, , Data Collection Plan (DCP)

- lastly, Run Chart, Control Chart, Regression

Let us now look at the qualities which can prove to be beneficial while preparation for the certification.

Required Skills set

For the purpose of earning this certification, the candidate will get benefit if the following qualities were earned –

- Firstly, devoting at least 30% to 40% of their production time on process improvement initiatives or activities, this will help in developing deeper understanding of the practical portions of the exam.

- Also, being able to solve quality related issues, which will help in understanding the consumer demands.

- In addition, working on Six Sigma, LEAN, KAIZEN or other projects which can keep him in touch with the syllabus and would save extra time spent on revising.

Career opportunities after Six Sigma Green Belt certification

These are some of the career opportunities available after you earn this Six Sigma Green Belt certification –

- Quality Department – Quality assurance manager/ Quality Compliance Analyst

- Project Department – Project quality manager /Project manager IT/ Work force management specialist

- Process Department – Operations Team Leader/ Process improvement specialist/ Senior Mechanical Engineer

- Finance Business Process Expert

- Six Sigma Green Belt Management Analyst

Market Demand and Average salary of The Six Sigma Green Belt Professional

Earning The Six Sigma Green Belt Certification can help you to earn valuable career opportunities in various companies across the globe. There is a great demand of certified lean six sigma professionals across the domains. Companies like Accenture, Sodexo, KPMG, Wipro, Myntra, Oakland, IBM etc. are having good demand for certified professionals.

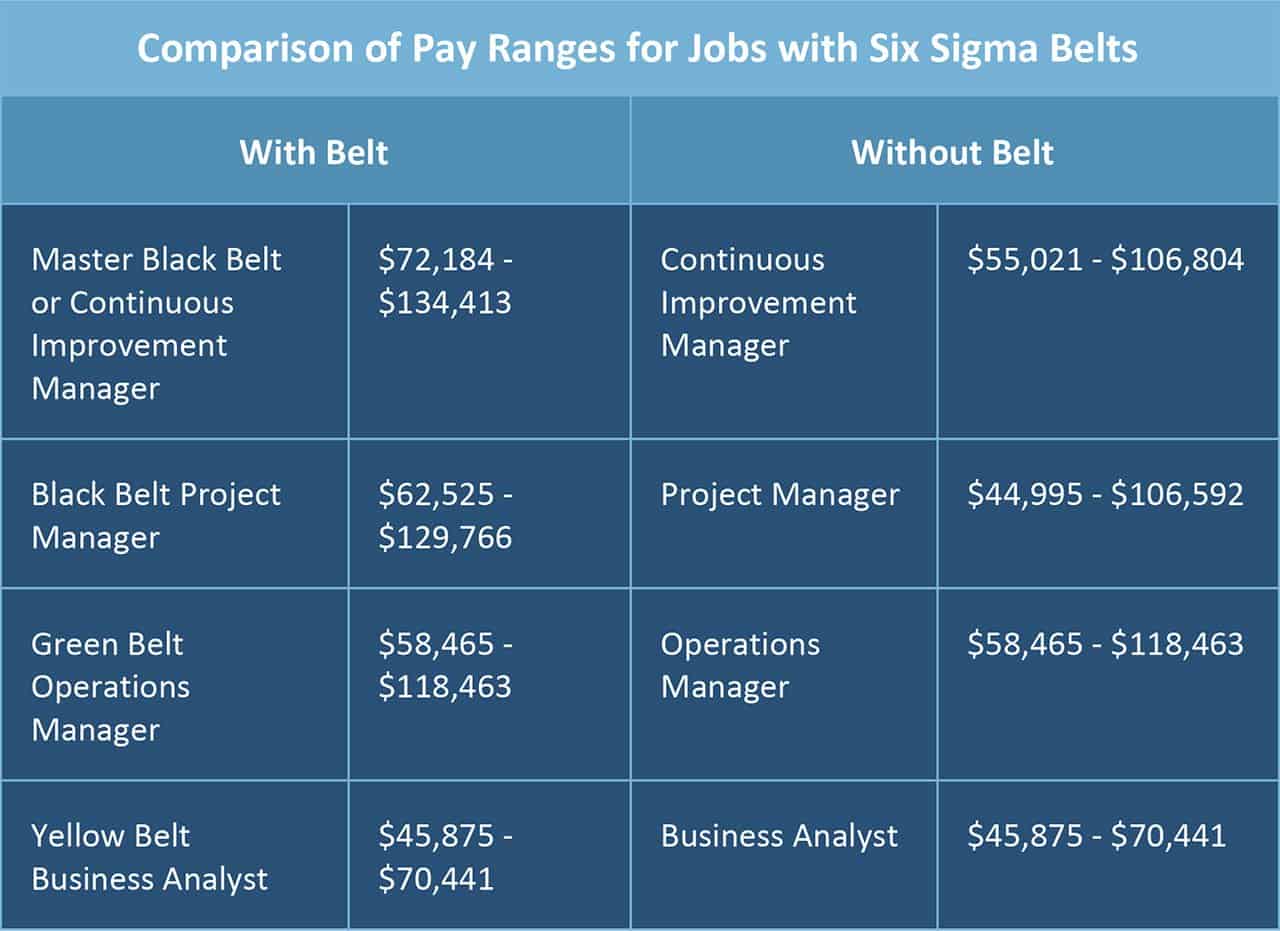

According to PayScale.com, the average salary for a Six Sigma Green Belt salary for 2017 was roughly between $65,000 and $79,000 per year. According to Indeed.com, the national average salary for a Certified Green Belt Professional is $72,000 per year in the United States. Find differences in the salary level of people with and without six sigma belts. Eventually the people who have this certification end up having good opportunities and more job opportunities as well. s per research by Salary.com, last done as of April 27, 2020, the average Six Sigma salary in United States is ranging from $84,800 to $1,10,400.

What is the use of Six Sigma Green Belt certification?

Looking at the above mentioned all the details about the market demand and skills that you will acquire through the whole process of earning this certification it must be pretty clear about the use of this certification. However, the benefits could be summarized as under –

- Six Sigma training proves as an excellent tool to deliver best performance in the competitive atmosphere and in turn climb the ladder of success faster and increase their salary structure.

- The career expansion opportunities are widened for a candidate as mentioned above and helps them to explore in the arena of their interest. Let us now look at some preparation resources which will help you to pass the exam with flying colors.

Now, we will look at the course outline which will help us to figure out the level of exam and the direction of preparation.

Course Outline for Six Sigma Green Belt certification

Find the course outline given below –

1. Six Sigma and Organizational Goals

- firstly, History and Evolution of Six Sigma

- also, Introduction to Six Sigma

- in addition, Characteristics of Six Sigma

- furthermore, Improvement Process and Transfer Function

- also, Contributions to Six Sigma

- subsequently, Six Sigma Projects

- in addition, Six Sigma Business Processes

- furthermore, Organizational Drivers

- Organizational Metrics and Process Improvement

2. Lean Principles and Six Sigma Projects

- firstly, Introduction to Lean Principles

- also, Lean Principles and Concepts

- furthermore, Application of Lean Six Sigma

- in addition, Theory of Constraints (TOC)

- furthermore, Valuable and Non-Valuable Activities

- lastly, Value Stream Mapping

3. Design for Six Sigma and FMEA

- firstly, Design for Six Sigma (DFSS)

- also, DFSS and Six Sigma Methodology

- furthermore, DFSS Methodologies

- in addition, Failure Modes and Effects and Analysis (FMEA)

- also, Risk Priority Number (RPN)

- lastly, Design FMEA and Process FMEA

DEFINE PHASE

4. Six Sigma – Project Identification

- firstly, Six Sigma Project and Methodology

- in addition, Six Sigma Benchmarking

- also, Components of a Process

- furthermore, Input and Output – Process Variables

- also, Project Stakeholder in Six Sigma

5. Voice of the Customer in Six Sigma

- firstly, Voice of the Business and Voice of the Customer

- also, Process of Collecting Customer Data

- subsequently, Effective Data Collection Techniques

- furthermore, Customer Requirements and QFD

- also, House of Quality (HOQ)

- lastly, HOQ Matrix

6. Six Sigma and Project Management

- firstly, Six Sigma – Project Charter

- also, Six Sigma – Project Scope

- in addition, Project Metrics – Six Sigma

- subsequently, Project Planning Tools

- Project Documentation in Six Sigma

- also, Project Risk Analysis

7. Six Sigma Management and Planning Tools

- firstly, Affinity Diagrams

- also, Interrelationship Digraph

- furthermore, Tree Diagram

- in addition, Prioritization Matrices

- also, Matrix Diagrams

- in addition, Process Decision Program Charts (PDPC)

- lastly, Activity Network Diagrams

8. Six Sigma Performance Metrics

- Performance Metrics

- Defects Per Unit (DPU)

- Defects Per Million Opportunity (DPMO)

- Rolled Throughput Yield (RTY)

- Process Capability Indices

- Cost of Poor Quality (COPQ)

9. Project Team Dynamics and Performance

- Six Sigma Teams

- Roles and Responsibilities of Six Sigma Team

- Six Sigma Team – Roles and Responsibilities

- Challenges of a Team

- Tools of Six Sigma

- Team Communication in Six Sigma

MEASURE PHASE

10. Process Analysis and Documentation

- Measuring Processes

- Process Mapping

- Process of Documentation

11. Probability and Statistical Distribution

- Probability and Events

- Rules of Addition and Multiplication

- Permutation and Combinations

- Statistical Distributions

- Binomial and Poisson Distribution

12. Data Classification, Sampling and Collection

- firstly, Data Types and Measurement

- also, Data Sampling Methods

- Six Sigma Data Collection Methods

- Strategies of Data Collection

13. Statistical and Graphical Presentation

- Fundamentals of Statistics

- Measures of Central Tendency and Dispersion

- Frequency Distribution

Graphical Methods

14. Measurement System Analysis

- Measurement System Analysis

- Precision in Measurement Systems

- Measurement Accuracy – Bias Study

- Measurement Accuracy – Linearity Study

- Percent Agreement

15. Performance and Process Capability Measurement

- Measuring Process Performance

- Process Capability Studies

- Indices of Process Capability and Performance

- Long-term Capability and Sigma Level

ANALYZE PHASE

16. Six Sigma – Hypothesis Tests for Variances and Proportions

- Paired Comparison T-Test

- Test for Variance

- Hypothesis Tests for Proportions

- ANOVA

- Chi-square Test

17. Six Sigma – Hypothesis Testing and Tests for Means

- Introduction to Hypothesis Testing

- Confidence Interval and Error Types

- Power and Sample Sizes

- Process – Hypothesis Testing

- One Sample Tests for Means

- Two-sample t-test for Means (Pooled)

18. Six Sigma – Multi-vari Studies, Correlation, and Linear Regression

- Multi – Variation Analysis

- Variation in Six Sigma

- Correlation and Correlation Coefficient

- Causation and Statistical Significance

- Linear Regression

IMPROVE PHASE

19. Six Sigma – Root Cause Analysis and Waste Elimination

- Root Cause Analysis

- Waste Reduction

- Tools of Waste Reduction

20. Design of Experiments

- Introduction to Design of Experiments

- Important Concepts in DOE

- Types of Effects

21. Six Sigma – Cycle Time Reduction and Kaizen Blitz

- Cycle Time Reduction

- Methods of Cycle Time Reduction

- Kaizen and Kaizen Blitz

CONTROL PHASE

22. Six Sigma – Control Charts

- Key Elements and Types of Control Charts

- Handling Control Charts

- Standard Control Charting Process

- Variable Data and Control Charts

- Attributes of Data and Control Charts

23. Six Sigma – Lean Tools for Process Control

- Total Productive Maintenance (TPM)

- Visual Factory

- Process of Applying Control Tools in Service

24. Six Sigma – Statistical Process Control and Control Plans

- Introduction to Statistical Process Control (SPC)

- Control Charts and Variations

- Selecting Variables for SPC

- Rational Subgrouping

- Developing and Implementing Control Plan

Now that we are done with the content outline, we shall now be moving on to explore the opportunities after one passes the certification.

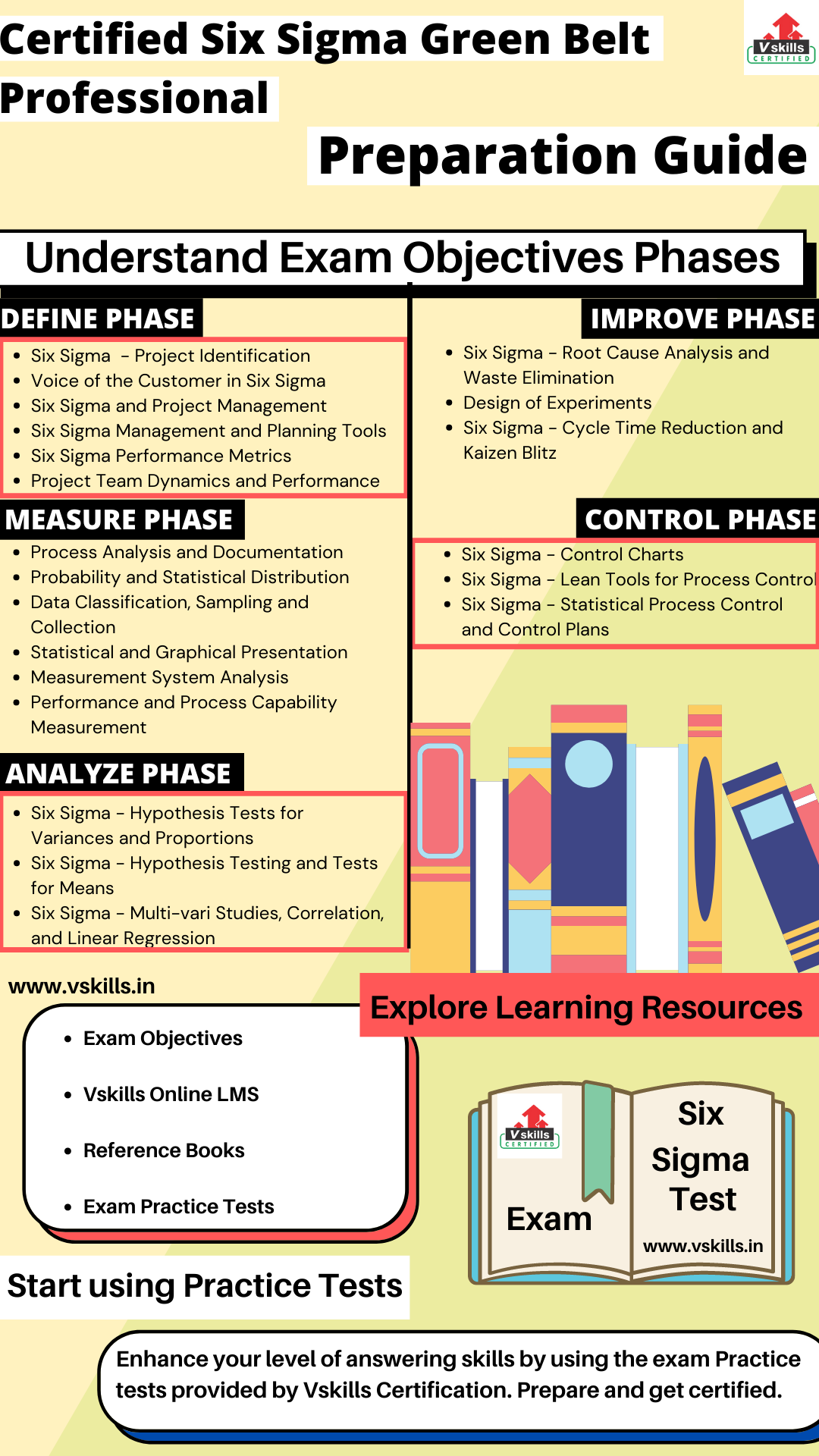

Six Sigma Green Belt Preparation Guide

There are numerous resources available for preparation. However you need to choose the resources that allow you to prepare in the best possible way and hit the bull’s eye. The resources that allow you prepare up to the apt level in the minimum time available can be the best ones on the table. Some resources that you can refer to are listed below –

VSkills Certification course for Six Sigma Green Belt

Vskills certification for Six Sigma – Green Belt Professional assesses the candidate as per the company’s need for deploying, managing and maintaining quality systems. The certification tests the candidates on various areas in lean and six sigma principles, DMEA, QFD, collecting and summarizing data, statistical analysis and process control.

This certification is specially designed to prepare you for a career in Quality Control and six sigma green belt –

You will gain following skills through these courses –

- How to solve quality problems

- In addition, Study statistical tools & techniques

- Furthermore, Know how to identify and eliminate errors and defects in a process

- Learn how to apply DMAIC ( Define, Measure, Analyze, Improve, Control)

Earning Vskills Six Sigma – Green Belt Professional Certification can help candidate differentiate in today’s competitive job market, broaden their employment opportunities by displaying their advanced skills, and result in higher earning potential.

Benefits of Certification

- Government Certification

- also, Certification valid for life

- furthermore, Lifelong e-learning access

- Free Practice Tests

- in addition, Get tagged as ‘Vskills Certified’ On Monsterindia.com

- lastly, Get tagged as ‘Vskills Certified’ On

Shine.com

Shine.com

The courses that you can cover for preparing this certification are –

Online Tutorials

There are many online sites that provide with the Online tutorials, online trainings and instructor-led trainings. Moreover, These programs are interactive enough and help in clearing the doubts in a very nice manner. Furthermore, The sites take whole liability in case you fail to clear the exam. They also provide every time doubt clearing service which helps you in clearing your doubts instantly. Visit the Online tutorials by VSkills for preparation.

Practice tests

Practice papers and test series are a way to determine the level of your preparation. In addition, They will help you identify weak parts of your preparation and will decrease the silly mistakes. Practicing is the key to qualifying any certification exam is no different. So, make sure to practice as much as you can. If you wish to strengthen your preparation process as well as boost your confidence, then you must try practice tests. Therefore, Try a free practice test now!