Role of Transportation and Logistics

Transportation and Logistics

Transportation means movement of products from the beginning of the supply chain to the customer. Transportation plays a significant role in any supply chain because products are rarely produced and consumed at the same location. An object produced at one point has very little value to the prospective customer unless it is moved to the consumption point. The success of any supply chain is closely linked to the appropriate use of transportation. Every company makes use of different modes and routes of transportation for maximum profitability.

Factors influencing Transportation Decision

There are two key players within any supply chain, one called the shipper and the other called the carrier. Shipper is the party that requires the movement of the product between two points in the supply chain and the carrier is the party that transports the products for the shipper.

Factors affecting transportation vary depending on whether one takes the perspective of a carrier or shipper – A shipper uses transportation to minimize the total cost of the product to be delivered while providing an appropriate level of responsiveness to the customer. Whereas a carrier makes investment decisions regarding the transportation infrastructure and makes operating decisions to try and maximize the return from these assets.

- Factors affecting decisions of carriers include – Vehicle related costs, Fixed costs, Trip related costs, Quantity related costs and Overhead costs

- Factors affecting shippers decision include – Transportation cost, Inventory cost, Facility cost, Processing cost and Service costs

Modes of Transport

- Truck Transport – It is one of the most dominant mode of transport. The truck industry consists of two sectors i.e. TL – Truck load and LTL – Less than truck load

- Package Carriers – It carry small packages ranging from letters to shipment weighing about 200-250 kgs.

- Railways – Railways are priced to encourage large shipment over a long distance

- Water Ways – It includes transportation by ships and boats used for bulk products

- Air Transport – includes small packages which are costly and time specific

- Pipeline – used for transport of natural gas, petroleum, oil and water

- Intermodal Transport – It uses more than one mode of transportation eg – truck and rail

Transportation network design options

There are various transportation-network design options that a company may implement to achieve the desired degree of response and lower costs associated with it. Types of Design Options –

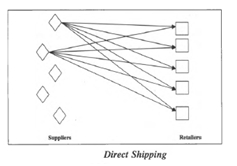

- Direct shipping – Involves shipping of products from the supplier to all its retail stores.

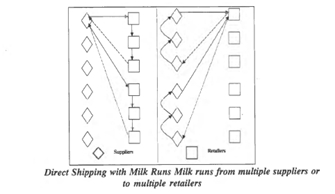

- Direct shipping with milk runs – A Miik Run is a route in which a truck either delivers a product from a single supplier to multiple retailers or goes from multiple suppliers to a single retailer.

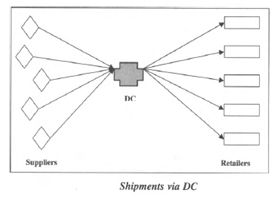

- Shipments via DC (distribution centre) – In this type of transportation design network, suppliers need not send shipments directly to the retailers. Retail chains are divided into common geographical areas and a centrally located DC is built for each of these regions. Suppliers then send their shipments to the DC and then the DC transfers the appropriate shipments to every retailer within its geographical region.

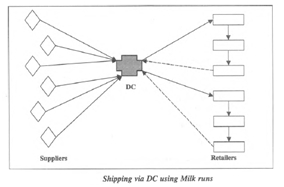

- Shipping via DC using Milk Runs – Milk runs are used from a DC when the lot sizes to be delivered to retailers are small. Milk runs are most important because they reduce the outbound transportation costs by consolidating small shipments.

- Customised tailored network – The transportation uses a combination of cross-docking, milk runs, truck loads and less than truck load carriers, along with package carriers in some cases.

Transportation Design Trade Offs

All transportation decisions in a supply chain network must be taken keeping in mind their impact on the supply chain costs, as well as the level of response provided to the customers. Tradeoffs when making transportation decisions are –

- Transportation cost and inventory cost trade off – Trade off between the transportation cost and the inventory cost is a significant one and must be considered when designing the supply chain network. The fundamental supply chain decisions involving this trade off are – Choice of transportation mode and inventory aggregation

- Transportation cost and customer response trade off – The transportation cost a supply chain incurs is related to the degree of response the supply chain aims to provide. Thus, a firm must consider a tradeoff between the degree of response and transportation cost when designing its transportation network.

Routing and Switching

Considering the investments made in the infrastructure, equipment and facilities vis-a-vis the operating expenses, carriers have realised the importance of good routing and scheduling of their fleet in order to decrease the costs, and in turn, increase the overall profitability of the firm and increase the customer response.

Routing and Scheduling of deliveries are the most important operational decisions related to transportation in any supply chain. With the help of proper routing and scheduling, managers can decide on the customers to be visited by a particular vehicle and also the sequence in which they have to be visited.

Most widely used Transportation software or Transportation management systems (TMS) used by large transportation and shipping companies are –

- Transportation analysis

- Traffic routing and Scheduling

- Freight rate maintenance and Auditing

- Vehicle maintenance

Tailored Transportation

Tailored transportation is nothing but customised transportation of products by using various types of transportation network and modes based on the product and the customer characteristics. Tailored transportation is a tool in the hands of supply chain managers to helps reduce the total costs to the firm.

With the help of tailored transportation, a firm is able manage each of its customers cost effectively and with suitable responsiveness, some of the things to be kept in mind while adopting tailored transportation are –

- Customer density and distance – Firms consider tailored transportation on the basis of customer density and distance from the warehouse while designing the transportation networks.

- Size of the customer – Firms must consider tailored transportation by size of the customer while designing transportation networks. Large customers can be supplied using a truck load carrier, whereas the smaller customers will require a less than truck load carrier or Milk Runs.

- Product value and demand – Firms must consider tailored transportation by product value and demand. The level of inventory aggregation and the modes of transportation used in a supply chain network should vary with the demand and value of the product. High value products within high demand must be subject to disaggregate cycle inventory and aggregate safety inventory.

Transportation in Practice

Transportation costs form a major fraction of the total supply chain costs, a thorough analysis is required by managers to select appropriate modes of transport in order to reduce costs and manage the level of response required. In order to achieve these two goals, a firm may have to fulfill the following conditions to make their transportation decisions effective –

- Align transportation strategy with competitive strategy – Company’s transportation strategy must support its competitive strategy. Functional incentives should be introduced to achieve this goal.

- Keep in mind both in-house and outsourced transportation – Supply chain managers must consider an appropriate combination of in-house (or company owned) transportation and outsourced transportation to meet their needs.

- Be compatible with e-commerce – Transportation systems must be able to provide on time delivery (i.e. needs to respond quickly) but must also be able to exploit the opportunity for aggregation; and even with competitors in some cases, they should be able to help reduce the transportation cost of small shipment.

- Use technology – Supply chain managers must use information technology available to them in order to decrease the transportation costs and increase response in their transportation networks.

- Allow design flexibility in transportation network – Uncertainty in demand and availability of transportation should be taken into account while designing transportation networks. If one ignores uncertainty in transportation, then there is a greater use of inexpensive and inflexible transportation modes that perform well as per planning.