Postponement and CRM in SCM

Postponement and CRM in SCM

The primary objective here is to understand the concept of postponement and its applicability to supply chain management. In the process of defining the concept of postponement, we shall also consider the concept that works best under Specific demand, product, and production preconditions. Further we will be illustrating the impact of postponement on company strategy, capabilities, processes, resources and infrastructure.

What is Postponement?

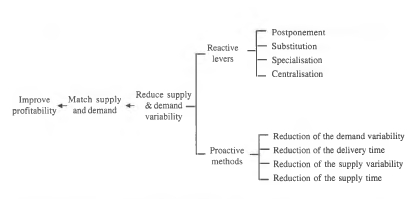

Postponement is said to belongs to a set of levers that are used in inventory management used to attack the variability of demand and supply. As a set of levers postponement can be divided into the following –

- Proactive Levers – Proactive levers directly attack the causes of variability

- Reactive Levers – Reactive levers help to cope with its consequences

Postponement is considered as a reactive lever for reduction of the demand and supply variability. In the process of employing tools like postponement, the final goal is to improve profitability by better matching supply with demand.

Optimal Postponement Preconditions

Optimal Postponement Preconditions

Implementation of postponement works best under certain demand, product and production preconditions.

What are the per-conditions of Demand?

- Fluctuation – It refers to the fluctation in demand due to factors like seasonal hikes in demand for Air Conditioners

- Unpredictability (like increased demand for high-tech products with a short product life)

- Urgency – It involves operating on short required order lead times relative to the production cycle (like UCB would not be able to run its full regular production cycle after finding out which jacket colors that sell best in the season).

- Differentiation – It is associated with distinct customer segments that require the company to provide a product line in which the products have different performance characteristics like different performance, technological or legal requirements on the same product in different countries.

- Negative correlation for the products in the product line such as success of one line of printers can have an adverse impact on the demand for the remaining lines of printers

What are the preconditions product line?

- High product value – These products have high unit value together with high inventory holding cost and high cost of oversupply. Here the concept of postponement is best applied when one particular component or step adds significantly high value. Only then it makes intuitive sense to delay it.

- High customization- These product lines are highly customized end products that are generally difficult to forecast demand on a product basis. Also, it is difficult to find alternative uses for these products and therefore their cost of oversupply is high. Due to which it becomes important to find out the production step holding most significant impact on customization of the product (point of product differentiation).

- High component commonality – The component commonality is defined as a high degree of shared components across the product line. In which case shared components result in inventory pooling effects and also shared production process steps. In which case the component commonality is taken one step further in the modularity concept, that uses sharing of bundles of the components instead of single components.

What are the preconditions of Production?

- Balanced process capabilities – It consists of capabilities, such as cost, time, quality and flexibility that are required to be kept in balance. Delaying the component production until shortly before the demand is known may imply producing in small batches.

- Availability and quality of the outside suppliers- To serve more flexible production needs, the outside suppliers need to possess similar capabilities in terms of flexibility of deliveries, speed of order fulfillment and quality of service.

- Availability of information and IT systems in place- It requires a steady flow of information required so that the company can effectively manage the balance between the supply and the demand.

Postponement Implementation

Postponement helps to greatly improve the flexibility capabilities of the Arms to employ it. However, the basic operations framework indicates that there is a link between capabilities and strategy on one hand and capabilities and resources and infrastructure on the other hand. Such that the companies who implement postponement will need to address these links.

Realignment of Processes

- Order taking -In this case the companies that used to collect customer orders on a monthly basis would require to shorten the information collection cycle time.

- Purchasing – Realignment of process requires flexible and frequent purchasing operations that are to be established.

- Manufacturing – If the installation of the most expensive components or the point of product differentiation is to be delayed as much as possible, change in the sequence and timing of manufacturing steps that may be required.

- Warehousing – Function of the warehouse under the postponement concept may have to be greatly expanded. Instead of being only a store and shipping location, the warehouse may need to take a more proactive approach and function as an order consolidation and customization center.

- Expedition – In this case more frequent and flexible deliveries may be required.

Realignment of Resources

- Human resources – all of the product, process and infrastructure changes outlined above will have an impact on the knowledge and skills the employees will need to possess. Order taking and purchasing employees will have to learn to manage shorter deadlines, warehousing employees will have to adopt new skills e.g., in assembling the products and accept greater responsibilities in matching the orders and shipping in time. This, in tum, will have an impact on hiring, training and compensation procedures.

- Supplies – requirements for suppliers’ reliability and timeliness may be significantly stepped up, which may require supplier switching and consolidation.

Realignment of Infrastructure

- Production and Warehousing premises – It may be required to reconfigure the plant and warehousing network so that the premises are close to the customers or to the distributors.

- Production equipment – It may be requires to set up and changeover times that needs to be decreased to increase flexibility on the production line.

- Information and IT systems – Information and IT systems is a major overhaul in information systems that may be needed, sometimes with a similar requirement on the suppliers and the customers, to provide an adequate support. One example of such a coordinated action is Vendor managed inventories (VMI).

Postponement Evaluation

Prior to embarking on the changes in its processes and infrastructure, the company implementing postponement is required to evaluate whether the costs associated with it do not exceed the expected benefits i.e., whether or not postponement is a winning proposition to implement depends on whether its incremental benefits outweigh the incremental costs it requires.

Postponement Cost

Postponement tend to increase company costs both directly and indirectly.

- Increase in direct cost can be caused by product or process redesign. For example HP printers for dual volt networks had higher unit cost than printers that were designed for one network only.

- Increases in indirect cost increases can be caused by the changes in the production and distribution processes with the consequent impact on the infrastructure and resources. The impact of postponement is not limited to the company implementing postponement, but it also affects the other players in the supply chain.

Suitability of Postponement for Companies

There are primarily three characteristics that stand out where postponement can have a huge effect such as demand uncertainty, substantial product proliferation, and importance of a quick response relative to the cycle time of producing the product or service. Such that the companies that display any of these characteristics are candidates for performance improvement through postponement and the more of the characteristics companies display, the better candidates they are.

Hewlett Packard

Hewlett Packard (HP) is known as a leader in the application of postponement techniques. One of the areas where they have done this most effectively is in customizing their printers close to the local markets where they are actually being sold. Traditionally, most computer peripheral manufacturers have built one plant for a major market, such as the Americas, Asia, or Europe and then shipped product from this plant to regional distribution centers (DCs) around that market.

CRM in Supply Chain Management

Customer Relationship Management (CRM), is a company-wide business strategy designed to reduce costs and increase profitability by establishing customer loyalty. CRM brings together information from all data sources within an organisation to give one, holistic view of each customer in real time. This allows customer facing employees in such areas as sales, customer support, and marketing to make quick yet informed decisions on everything from cross-selling and upselling opportunities to target marketing strategies to competitive positioning tactics.