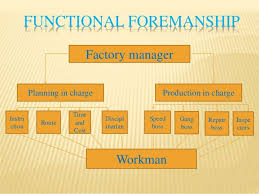

Frederick Winslow Taylor, also known as the “Father of Scientific Management”, believed that certain scientific techniques could increase the productivity at the shop-door level. After conducting various experiments, he came up with the Techniques of Scientific Management. One of those techniques was Functional Foremanship.

Taylor thought that one supervisor could not possess all the qualities required to lead the workers. Hence, he suggested this technique under which one worker would be supervised by eight specialist foremen. He separated planning of work from execution of work. The eight foremen are listed below:

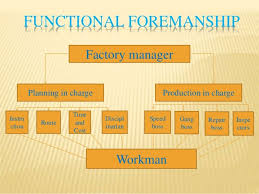

PLANNING INCHARGE

- ROUTE CLERK: His duty is to draft a chronological order of doing various tasks in the factory to achieve the required targets efficiently and effectively. His orders must be followed strictly by all the workers.

- INSTRUCTION CARD CLERK: His work is to formulate instructions for the workers of the factory. The work must be performed within the limits of such instructions.

- TIME AND COST CLERK: He has to prepare a realistic and achievable timetable for doing all the work at the shop floor level. He must also regularly maintain records of the cost of the work done.

- DISCIPLINARIAN: His job is to see that all the rules are being enforced and followed by the workers and if not, he has the authority to take the required action. He is supposed to maintain discipline among workers too.

PRODUCTION INCHARGE

- GANG BOSS: He is supposed to ensure that all the tools and equipments are assemble and arranged in the plant. He must also tell the workers how to operate the machinery efficiently.

- SPEED BOSS: His job is to ensure that all the work targets are achieved, i.e., the work is done on time. He must make sure that the workers are doing their tasks at the right speed.

- REPAIR BOSS: He must take care that each worker keeps his machines and tools in the proper working condition. It ensures that the machines are clean and rust free.

- INSPECTORS: His job is to make sure that the quality of the work done in the factory is in accordance with the particular standard set.

To conclude, all the above officers have an essential duty. They help in increasing the overall productivity of the organisation, reducing costs and saving time.

17 Comments. Leave new

Well-structured article!

Good Points 🙂

The points and the presentation 😀

Perfect subtopic 😀

Adequate amount of info 😀

GOod work 😀

As taylor said scientific management is the art of knowing exactly what you want your men to do and then seeing that they do it in the best possible manner very well written commendable

Very nearly explained.

Neatly*

nice

Great work!

infomative

Nice!

Nice and informative.

Apt and interesting to read.

Well articulated

Good work

Good to read.

very well explained 🙂

Another new thing to read. pretty good content.