Production control is the activity of monitoring and controlling any particular production or operation. Production control is often run from a specific control room or operations room. With inventory control and quality control, production control is one of the key functions of operations management.

Production control is the task of predicting, planning and scheduling work, taking into account manpower, materials availability and other capacity restrictions, and cost so as to achieve proper quality and quantity at the time it is needed and then following up the schedule to see that the plan is carried out, using whatever systems have proven satisfactory for the purpose.

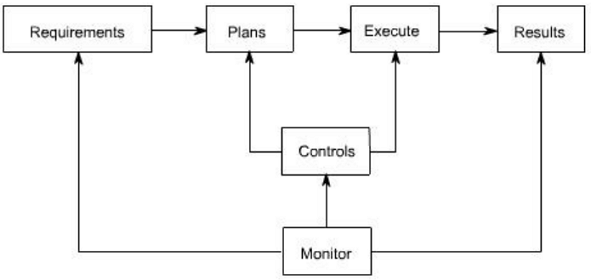

- Production control is a mechanism to monitor the execution of the plans. It has several important functions, as

- Making sure that production operations are started at planned places and planned times.

- Observing progress of the operations and recording it properly.

- Analyzing the recorded data with the plans and measuring the deviations.

- Taking immediate corrective actions to minimize the negative impact of deviations from the plans.

- Feeding back the recorded information to the planning section in order to improve future plans.

A block diagram depicting the architecture of a control system is shown

Need

Production process of an enterprise is a system consisting of material, labour and equipment combined together by some dependence imposed by operations. Input factors in the process are always uncontrollable. The controller of a production process tries to control the output so that it is in conformity with the target set by the marketing department.

Production control tries to channelise the manufacturing process in such a manner that goods and services are produced according to the requirements of the consumer, i.e., of right quality, shape and quantity at the desired time.

In the present era of cut-throat competition, production control is a boon for an enterprise. It tries to take corrective measures whenever there is some deviation from the planned strategy. Goetz has rightly said that “Management planning seeks consistent, integrated and articulated programmes.” Production control aims to fulfill these needs.

In the report on the elimination of waste in industry. President Noover’s committee states that “Production control is the hallmark of production efficiency. It is a necessity and not a luxury; a profitable investment and not an expense.”

Objectives

The success of an enterprise greatly depends on the performance of its production control department. The production control department generally has to perform the following functions:

- Provision of raw material, equipment, machines and labour.

- To organise production schedule in conformity with the demand forecast.

- The resources are used in the best possible manner in such a way that the cost of production is minimised and delivery date is maintained.

- Determination of economic production runs with a view to reduce setup costs.

- Proper co-ordination of the operations of various sections/departments responsible for production.

- To ensure regular and timely supply of raw material at the desired place and of prescribed quality and quantity to avoid delays in production.

- To perform inspection of semi-finished and finished goods and use quality control techniques to ascertain that the produced items are of required specifications.

- It is also responsible for product design and development.

Thus, the fundamental objective of production control is to regulate and control the various operations of production process in such a way that orderly flow of material is ensured at different stages of the production and the items are produced of right quality in right quantity at the right time with minimum efforts and cost.

Levels of Production Control

Production Control starts with some particular goal and formulation of some general strategy for the accomplishment of desired objectives. There are three levels of production control namely programming, ordering and dispatching. Programming plans the output of products for the factory as a whole.

Ordering plans the output of components from the suppliers and processing departments. Dispatching considers each processing department in turn and plans the output from the machine, tools and other work centres so as to complete the orders by due date.

Types

One type of production control is the control of manufacturing operations.

- Production planning and control of the when and where.

- Production control and supply chain management

Management of real-time operational in specific fields.

- Production control in the television studio in a production control room

- Master control in television studio

- Production control in spaceflight in a Mission Operations Control Room

Production control is just one of multiple types of control in organizations. Most commons other types are:

- Management control, one of the managerial functions like planning, organizing, staffing and directing. It is an important function because it helps to check the errors and to take the corrective action so that deviation from standards are minimized and stated goals of the organization are achieved in a desired manner.

- Inventory control, the supervision of supply, storage and accessibility of items in order to ensure an adequate supply without excessive oversupply.

- Quality control, the process by which entities review the quality of all factors involved in production.