The basis of Just-In-Time (JIT) is the concept of ideal production. It centers on the elimination of waste in the whole manufacturing environment, from raw materials through shipping. Just-In-Time is defined as “the production of the minimum number of different units, in the smallest possible quantities, at the latest possible time, thereby eliminating the need for inventory.

Just in time (JIT) is a production strategy that strives to improve a business’ return on investment by reducing in-process inventory and associated carrying costs. To meet JIT objectives, the process relies on signals or Kanban between different points, which are involved in the process, which tell production when to make the next part. Kanban are usually ‘tickets’ but can be simple visual signals, such as the presence or absence of a part on a shelf. Implemented correctly, JIT focuses on continuous improvement and can improve a manufacturing organization’s return on investment, quality, and efficiency. To achieve continuous improvement key areas of focus could be flow, employee involvement and quality.

An important aspect of JIT, is that the production has to switch over to Pull System from Push System as

PUSH SYSTEM – In this system, production quantity is based on the demand and stock in hand. The components are made in step-by-step approach in a sequential manner using the time standards for each operation.

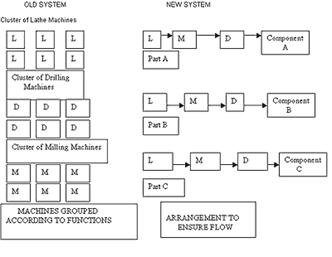

PULL SYSTEM – In this method, the required quantity is withdrawn by the final process centre from the previous process work centre and in turn that process work centre withdraws the required quantity from its previous centre and so on. Thus this procedure works in reverse order. This is like walking into the supermarket and trying what we want, when we want and how much we want. Another significant aspect is that apart from flow type process even the layout of machines may also undergo change. Example is as

Just in Time (JIT) pioneered by Toyota in the 1950s and adopted successfully all over the world entails eliminating waste and improving product quality to maximize returns on investment. The basic JIT principles are to make only what is needed, when needed, and in the amount needed.

Elimination of Waste

The core principle objective of Just in Time (JIT) is to improve process efficiency by eliminating waste. Toyota’s Fujio Cho defines waste as “anything other than the minimum amount of equipment, materials, parts, and workers, which are absolutely essential to production” (Suzaki, 1987). The focus is not quick or more production but, to eliminate waste of any kind which has no value addition. JIT reduces costs and increase productivity by addressing the root of the problem by eliminating the “muda”.

Muda is a Japanese term meaning “waste” as, lean manufacturing is an Japanese management philosophy hence, Japanese terms and concepts are used extensively. There are 7 mudas or seven types of waste that are found in a manufacturing process which are

- Overproduction – An protective or “just in case” mindset usually results in overproduction. Producing more than the customer requires is waste. It causes other wastes like inventory costs, manpower and conveyance to deal with excess product, consumption of raw materials and installation of excess capacity.

- Needless Inventory – Inventory at any point is a no value-add as it ties up financial resources of the company and is exposed to the risk of damage, obsolescence, spoilage, and quality issues. It also needs space and other resources for proper management and tracking. Large inventories also cover up process deficiencies like equipment problems or poor work practices.

- Defects – Defects and broken equipment results in defective products and subsequently customer dissatisfaction, which need more resources for solving. Shipping damage is also taken as a defect. Any process, product, or service that fails to meet specifications is also a waste.

- Non-value Processing – It is also called over-processing, for which more resources are wasted in production, their wasted movement and time. Any processing that does not add value to the product is waste like in-process protective packaging. It is primarily due to extra or unnecessary manufacturing steps, using older and outdated methods or not having standard work plans.

- Excess Motion – Unnecessary motion which is also a waste occurs due to poor workflow, poor layout, housekeeping, inconsistent and undocumented work methods or lack of standardized procedures or even a deficiency in employee training. It is usually hidden as it’s not easily evident, but careful observation and worker’s communication can highlight it.

- Transport and Handling – It focus on shipping damage and includes pallets not being properly stretch wrapped (wasted material), or a truck is not loaded to use floor space efficiently or in handling, setting up or fixing a wrapping machine. Material should be shipped directly from the vendor to the location in the assembly line where it will be used also called as point-of-use-storage (POUS).

- Waiting – These are wastages in time, usually due to broken machinery, lack of trained staff, shortages of materials, inefficient planning, and waiting for material, information, equipment, tools, etc. It leads to slowed production, delayed shipments, and even missed deadlines.

There are other types of waste in other places which are

- Confusion – It is due to misinformation

- Underutilization of available employees (of their skills and knowledge ) and facilities

Elimination of these wastes is discussed next though it can be a long and difficult task, but the results of improved productivity and profits are what it aims for.

Quality at the Source (Jidoka)

Jidoka or ensuring quality at the source ranks amongst the major JIT principles. This principle entails identification and correction of problems at the manufacturing stage itself, as soon as it occurs.

JIT provides for jidoka through automation that caters to the automatic working of the assembly line and complete shut down upon detection of error. The production line resumes only after rectification of the error.

Jidoka makes inspection and quality control a part of the production process rather than a separate activity, and places the responsibility for quality on everyone in the company rather than the quality team alone.

Simplification

The third of the major JIT principles is simplification or using minimum resources to attain process efficiency. The JIT principle holds that excess of any kind masks problems such as low quality raw materials, unreliable vendors, defects in machinery, and the like. Removing the excess makes problems apparent.

JIT systems strive to attain zero work in process inventory buffers and zero ending finished goods inventory to ensure smooth process flow, elimination of storage space, and cost savings. JIT promotes a demand driven “pull” system where the process starts when the customer places an order that triggers the production, which in turn triggers a call for resources. Each stage in the production process manufactures only what is required for the next stage. “Kanbans” or instructions, usually by cards, provide each worker with specific instructions on what to do and what to use.

Cellular Manufacturing System

Group technology or Cellular manufacturing is another major JIT principle. The Cellular manufacturing system advocates that segmented and product focused manufacturing is much simpler than a linear process oriented manufacturing.

JIT institutes strategic capacity management techniques such as multiple small machines instead of a large bulky machine that requires constant production for profitability and others towards this end.

Respect for People

Among the major JIT principles is respect for people at all levels, be it employees, customers, suppliers or management. Success of JIT depends on identification of what the customer needs and fulfilling the request in the best possible manner.

Success of JIT depends on

- clear and effective communication among all the stakeholders

- employees empowered to make decisions and cross-trained to handle many machinery to ensure smooth flow of the product

- suppliers understanding and fulfilling demand for specific components at the right time

The management that respects people and works towards such people related critical success factors succeeds in reaping the benefits of JIT.