Total Productive Maintenance is an all-inclusive way of equipment maintenance that attempts to obtain perfect production (zero defects). The equipment is expected to have zero breakdowns, slow runs, or defects. The Vskills Certified Total Productive Maintenance Professional course is an industry-leading program that promotes individuals and companies with comprehensive skills and knowledge set for workforce development and business excellence.

Certified Total Productive Maintenance Professional aims to:

- Improve equipment effectiveness

- Achieve autonomous maintenance

- Plan maintenance

- Train all staff in relevant maintenance skills

- Achieve early equipment management

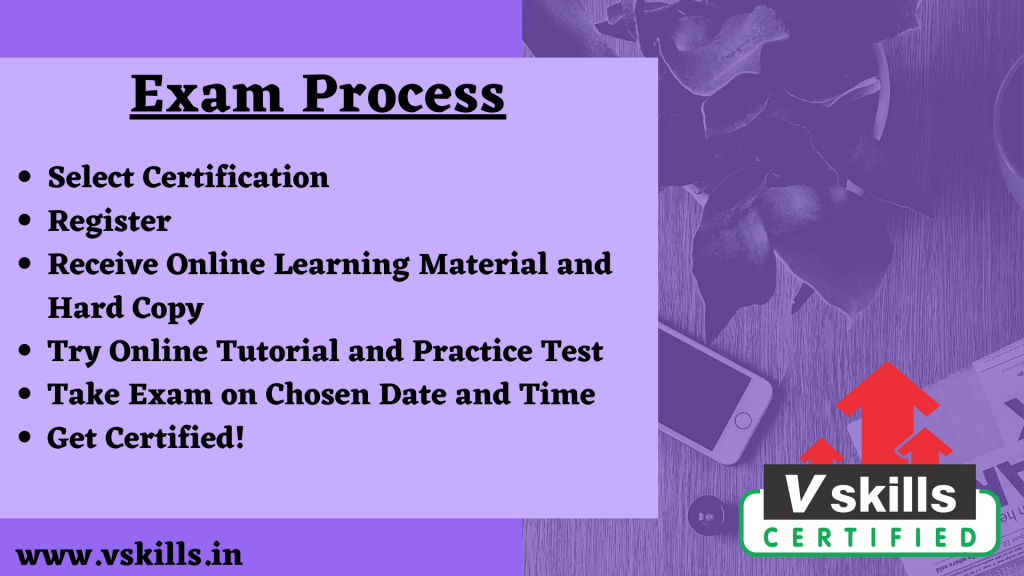

Exam Overview

The Vskills Certified Total Productive Maintenance Professional Course is intended for professionals and graduates wanting to excel in their chosen areas. It is also well suited for those who are already working and would like to take certification for further career progression. Earning Vskills Total Productive Maintenance Professional Certification can help candidate differentiate in today’s competitive job market, broaden their employment opportunities by displaying their advanced skills, and result in higher earning potential.

Vskills being India’s largest certification provider gives candidates access to top exams as well as provides after exam benefits. This includes:

- Become Government Certified Professional!

- The Certification is valid for life.

- Candidates will get lifelong e-learning access.

- Access to free Practice Tests.

- Candidates will get tagged as ‘Vskills Certified’ On Monsterindia.com and ‘Vskills Certified’ On Shine Shine.com.

Exam Details

- Exam Duration: 60 minutes

- Vskills Exam Code: VS-1567

- Number of questions: 50

- Maximum marks: 50

- Passing marks: 25 (50%)

- Exam Mode: Online

- There is NO negative marking in this module.

Course Outline

Vskills Certified Total Productive Maintenance Professional exam covers the following topics –

TPM Basics

- Quality and Relevance

- TQM

- Lean Basics

- Lean Value and Techniques

- 5S

- TPM Basics

- TPM Principles

TPM Pillar 1 – Jishu Hozen (Autonomous Maintenance)

- What is Jishu Hozen?

- Goals of Jishu Hozen

- Autonomous Maintenance Effects

- Operator Skill Levels

- Initial Clean

- Manager’s Model and Pilot Teams

- Visual Controls

- Activity boards

- The One Point Lesson (OPL)

TPM Pillar 2 – Kobetsu Kaizen or Continuous Improvement

- What is Kobetsu Kaizen?

- Equipment Losses

- Causal Factor Relationships

TPM Pillar 3 – Planned Maintenance

- What is Planned Maintenance?

- Time-Based Maintenance

- Usage-Based Maintenance

- Condition-Based Maintenance

- Predictive Maintenance

- Closed-Loop Automation

- Corrective Maintenance

- Effective PM

- Reliability Centered Maintenance

TPM Pillar 4 – Hinshitsu Hozen or Quality Maintenance (QM)

- Quality Maintenance Basics

- Quality Maintenance Principles

- Quality Maintenance Analysis Tools

- Quality Maintenance Stages

- QM Aims

- The Figure-of-Eight Method for Quality Maintenance

TPM Pillar 5 – Materials Planning, Design and Equipment Control

- Maintenance Prevention

- Early Equipment Management

TPM Pillar 6 – Education & Training

- Need for Training and Development

- Skills

- Phases of Skills

- Skill Evaluation

TPM Pillar 7 – Office TPM Pillar

- Administrative TPM

- P Q C D S M and Office TPM

- Implementing office TPM

TPM Pillar 8 – Safety, Health and Environment

- Safety, Health & Environment Basics

- Why-Why Analysis

- Industrial Accident Phases

- Environmental Safety

- A Case Study

Preventive and Predictive Maintenance

- Preventive Maintenance:

- Designing a Preventive Maintenance Program

- Preventive Maintenance Tools

- Predictive Maintenance

- Predictive Maintenance Technologies

- Predictive Maintenance Working

- Data preparation for predictive maintenance

- Modeling Techniques for Predictive Maintenance

- Training, validation, and testing methods for predictive maintenance

Equipment Failures

- Age-related failure mode

- Non-age-related failure mode

- Failure Analysis Tools

- Five Whys

- Ishikawa/Fishbone Diagram

- Cause-and-Effect Analysis/Causal Factor Tree

- Failure Modes and Effects Analysis

- Fault or Logic Tree Analysis

- Barrier Analysis

- Change Analysis/Kepner-Tregoe

- Statistical Tools

- Data Analytics

Overall Equipment Effectiveness (OEE)

- What is OEE (Overall Equipment Effectiveness)?

- OEEE Example

- The Six Big Losses

- SMED

Implementing TPM

- Impediments

- TPM Implementation Phases

Spare Parts Management

- What is Spares parts management?

- Spares Parts Inventory Analysis

Team Management

- Team Building

- Team Communication

- Team Socializing

- Team Culture

- Team Motivation

Change Management

- Overview of Change Management

- Recognizing Obstacles to Change

- Introducing Change

- Managing Change

- Eight-Step Change Management Process

- Strategies for Effective Implementation of Change

- Leading Change

- The CHANGE Model

- Leading through Change

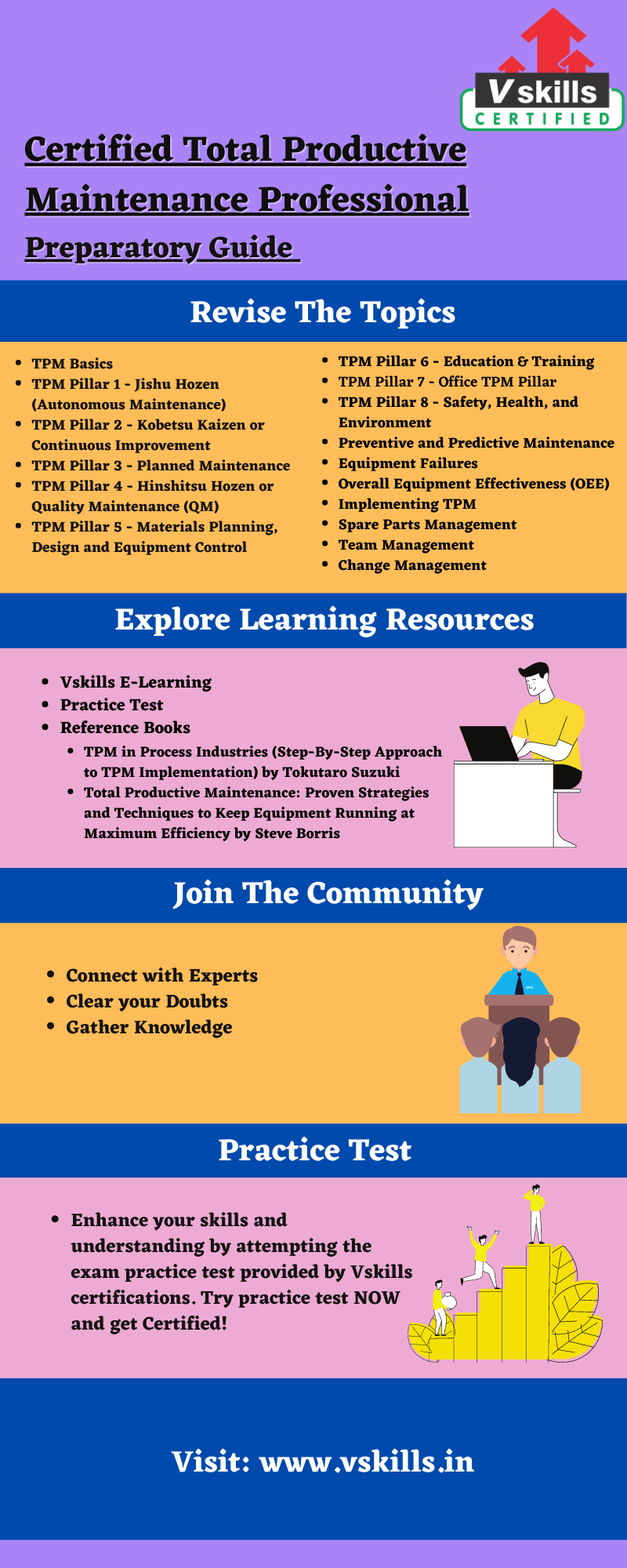

Preparation Guide

Candidates brewing for the Certified Total Productive Maintenance Professional exam should recognize the importance of exam resources. During the exam preparation, it is important to get all the necessary exam study sources. This will provide the benefit to understand the concepts and meaning more precisely. In the preparation guide, we will review some of the most significant resources to help the candidate prepare well for the exam.

Exam Objectives

For every examination, the first task should be to get all the exam relevant details including the important contents and its topic. With complete exam objectives, the candidate’s exam preparation time is better spent because they already know what to study. For this exam, the topics include:

- TPM Basics

- TPM Pillar 1 – Jishu Hozen (Autonomous Maintenance)

- TPM Pillar 2 – Kobetsu Kaizen or Continuous Improvement

- TPM Pillar 3 – Planned Maintenance

- TPM Pillar 4 – Hinshitsu Hozen or Quality Maintenance (QM)

- TPM Pillar 5 – Materials Planning, Design and Equipment Control

- TPM Pillar 6 – Education & Training

- TPM Pillar 7 – Office TPM Pillar

- TPM Pillar 8 – Safety, Health, and Environment

- Preventive and Predictive Maintenance

- Equipment Failures

- Overall Equipment Effectiveness (OEE)

- Implementing TPM

- Spare Parts Management

- Team Management

- Change Management

Vskills Online Learning Material

Vskills provides candidates a way to prepare for the exam using the online learning material for existence. The online material for this is regularly updated. Moreover, e-learning is bundled with hard copy material which encourages candidates to enhance and update the learning curve for superior and better opportunities. The candidate can also download the sample chapter for the Certified Total Productive Maintenance Professional exam.

Vskills Brochure

Vskills also provides a brochure for the Certified Total Productive Maintenance Professional exam. The brochure contains all the necessary related to the exam such as details, sample papers, important information, course outline, etc.

Books for Reference

The next step in the preparatory guide should be books and study guides. The candidate needs to find those books which are enriched with information. Finding a good book may be a difficult task, but in order to gather knowledge and skills, the candidate has to find, read, and understand. The candidate can try the following:

- TPM in Process Industries (Step-By-Step Approach to TPM Implementation) by Tokutaro Suzuki

- Total Productive Maintenance: Proven Strategies and Techniques to Keep Equipment Running at Maximum Efficiency by Steve Borris

Practice Test

Practice tests are the one who ensures the candidate about their preparation for the exam. The practice test will help the candidates to acknowledge their weak areas so that they can work on them. There are many practice tests available on the internet nowadays, so the candidate can choose which they want. Try the practice test here!