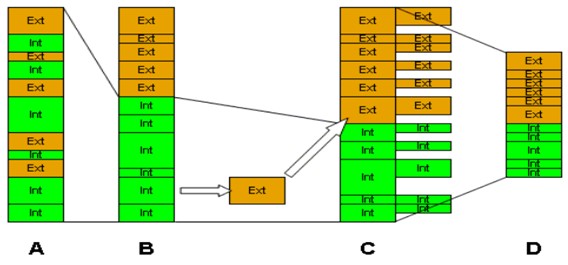

Shingo identifies four stages in SMED application which are

Stage 0- Preliminary Stage: Internal and External Setups are Mixed

SMED differentiates between internal setup and external setup. Internal setup consists of setup operations that can only be done while the machine is stopped. Such operations may include mounting or removing dies and fixtures. External setup includes setup operations that can be done while the machine is running. Operations like transporting dies and fixtures to and from the machine and ensuring the correct tools and parts are on hand and functioning before changeover are all examples of external setups. During the preliminary stage no effort is invested in differentiating external and internal setup, so external setup is often performed while the machine is stopped.

Stage 1 – First Stage: Separate Internal and External Setups

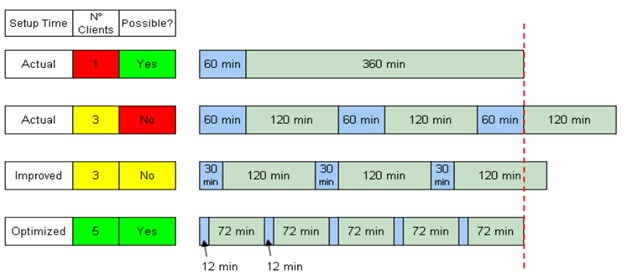

Setup time is defined when the last good product is completed by a resource and ending when the first good product is produced consistently, without further adjustments. Hence, setup time cannot be less than the internal setup and should not be more than the internal setup. Therefore, care should be taken to perform all external setup while the machine is running (either before or after the changeover).

For example, transporting the new die to the press should be done before the changeover begins, and transporting the old die to storage should be done after the changeover. These two activities are both external setups. If the operator cannot do these jobs while the machine is running, it may be justified to assign another person to do it. Typically, the first stage requires very small investments in hardware, if at all.

Separate the internal from the external tasks and then improve their efficiency as

Stage 2 – Convert Internal Setup to External Setup

Once no external setups are performed while the machine is waiting, a good way to reduce the setup further is to analyze the internal setup carefully and see which activities can be transformed to external setup. For example, Shingo cites a case where by using an extra table for a planer the new job could be set up while the old one was running with the other table on the machine. Then, the tables were exchanged in internal setup. This may require a small investment in hardware (an extra table), but it can alleviate the need for an extra planer.

Modern machine tools, notably some models made by Toyota, include multiple tables that are very easy to exchange to achieve this benefit (palletizing).

Improvement in successive runs with learning from each run and improvements applied before the next. The diagram below shows four such ruins and improvement thereof

Stage 3 – Streamline Both Internal and External Setups.

Transforming after separating internal and external setups is very beneficial for bottleneck machines, or to increase production lead time. Though the setup itself may be cut significantly, the total amount of work may not be reduced. Thus, to increase the number of setups, enough manpower is needed to perform the external setups.

To improve further, reduce the total setup effort by streamlining all setup activities, both internal and external. Examples: avoiding the need for adjustments by providing stops that locate the new die exactly at the right spot; using dies with standardized external dimensions that avoid the need to adjust the stroke of the press; using one-turn fasteners, instead of traditional nuts and bolts that require many turns; using rollers and pushing the old die out by inserting the new die in.

Shingo cites mechanization as a fourth stage, but says that it is very rarely justified. According to Shingo, one can typically reduce setups from up to 24 hours down to three or four minutes without any mechanization. Then, mechanization can gain another minute or two, and reduce the setup to the range of one to three minutes. But, the investment is not likely to be justified when viewed this way.