Plastic is an organic substance consisting of natural or synthetic binders or resins with or without moulding compounds. Plastics are capable of flow when necessary heat and pressure are applied.

A plastic material is any of a wide range of synthetic or semi-synthetic organic solids that are moldable. Plastics are typically organic polymers of high molecular mass, but they often contain other substances. They are usually synthetic, most commonly derived from petrochemicals, but many are partially natural.

Composition

Most plastics contain organic polymers. The vast majority of these polymers are based on chains of carbon atoms alone or with oxygen, sulfur, or nitrogen as well. The backbone is that part of the chain on the main “path” linking a large number of repeat units together. To customize the properties of a plastic, different molecular groups “hang” from the backbone (usually they are “hung” as part of the monomers before the monomers are linked together to form the polymer chain). The structure of these “side chains” influence the properties of the polymer. This fine tuning of the repeating unit’s molecular structure influences the properties of the polymer.

Most plastics contain other organic or inorganic compounds blended in. The amount of additives ranges from zero percentage (for example in polymers used to wrap foods) to more than 50% for certain electronic applications. The average content of additives is 20% by weight of the polymer. Many of the controversies associated with plastics are associated with the additives. Organotin compounds are particularly toxic.

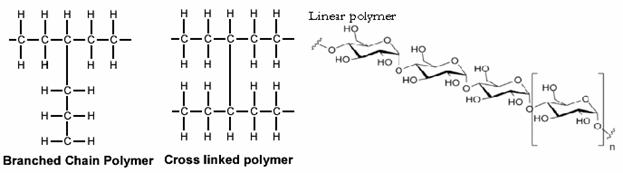

Classification of polymer structures

- Branched chain structures

- Cross-linked structures

- Linear structures

- Networking structures

Thermoplastics and thermosetting polymers

There are two types of plastics: thermoplastics and thermosetting polymers. Thermoplastics are the plastics that do not undergo chemical change in their composition when heated and can be molded again and again.

Examples include polyethylene, polypropylene, polystyrene and polyvinyl chloride. Common thermoplastics range from 20,000 to 500,000 amu, while thermosets are assumed to have infinite molecular weight. These chains are made up of many repeating molecular units, known as repeat units, derived from monomers; each polymer chain will have several thousand repeating units.

Thermosets can melt and take shape once; after they have solidified, they stay solid. In the thermosetting process, a chemical reaction occurs that is irreversible. The vulcanization of rubber is a thermosetting process.

Crystalline and amorphous plastics

Some plastics are partially crystalline and partially amorphous in molecular structure, giving them both a melting point (the temperature at which the attractive intermolecular forces are overcome) and one or more glass transitions (temperatures above which the extent of localized molecular flexibility is substantially increased). The so-called semi-crystalline plastics include polyethylene, polypropylene, poly (vinyl chloride), polyamides (nylons), polyesters and some polyurethanes. Many plastics are completely amorphous, such as polystyrene and its copolymers, poly (methyl methacrylate), and all thermosets.

Properties of plastics

- Chemical resistance to moisture, corrosive elements and solvents. Hence they are used to convey chemicals.

- Dimensional Stability

- Ductility

- Durability

- Electric insulation

- Fire resistance

- Low melting points

- High optical properties (transparency and translucency)

- Sound absorption

- Recyclable

- Low thermal conductivity

- Light weight

Fiber glass reinforced plastic (FRP)

The FRP is manufactured by using two materials in conjunction with each other to form a composite material of different properties altogether. These plastics provide stiffness and strength while the resin provides a matrix for the transfer of loads to the fibers.