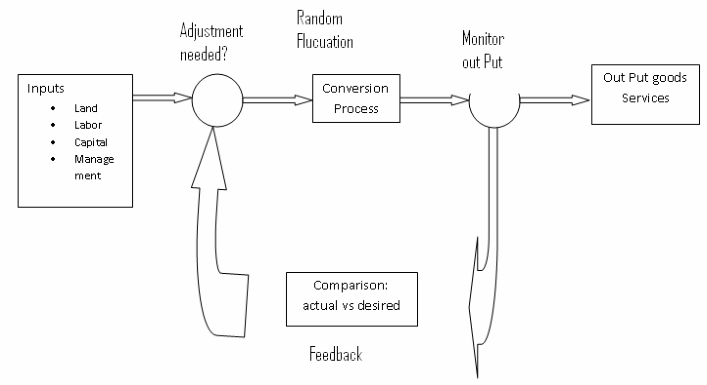

The operation function of an organization is the part that produces the organization’s products. The product may be physical goods or services. This function performs several activities to ‘transform’ a set of inputs into a useful output using a conversion process. The conversion process is the process of changing inputs of labor, materials, capital and management into outputs of goods and services. The basic elements of a conversion process are shown in the Figure 1.1

Figure 1.1 Basic Elements of Conversion Process

The production process consists of number of activities and operations. These operations and activities can be applied in different combinations and order to achieve the desired objective. The operations can be purchase of raw materials, maintenance of inventories, transportation of goods etc. The combination of two or more constitutes a system. In any production process two or more systems can be combined in series or parallel e.g. number of factories producing produce similar products to supply several markets areas then they constitute a parallel system. According to Webster “System is a regularly interacting or interdependent group of items forming a unified whole.” Any systems may have many components and variation in one component is likely to effect the other components of a system e.g. change in rate of production will affect inventory, overtime hours etc.

Broadly speaking an ‘operation function’ or operations management is a systematic approach to address all the issues pertaining to the transformation process that converts some inputs into outputs that are useful and could fetch revenue to the organization. Four aspects of this definition merit closer attention.

A systematic approach involves understanding, nature of issues and problems to be studied, establishing measures of performance, collecting relevant data, using scientific tools and techniques to analyze and effective and efficient solutions to the problem. Therefore, for successful operation management, the focus should be on developing a set of tools and techniques to analyze problems within operation systems.

The second aspect of operation management pertains to addressing several issues that an organization faces. These issues vary markedly in terms of the time horizon, the nature of the problem to be solved and commitment of the required resources, the problems may include deciding how to re-route jobs when a machine breaks down on a shop floor or how to handle a surge in demand in a service systems. On the other hand, decisions such as where to locate the plant, what capacity to build in the system and what type of products and services need to be offered to the customers is to be done? Operation management provides alternative methodologies to address such wide-ranging issues to an organization.

Transformation processes are central to operation systems. The transformation process ensures that inputs are converted into useful outputs. Therefore, the focus of the operation management is to address the various aspects of design in the transformation process as well as planning and operational control.

Finally, the goal of operation management is to ensure that through careful planning and control of operations the organization is able to keep the costs. In order to ensure this an appropriate performance evaluation system is required. Therefore the operation management discipline also involves the development of such a system of performance evaluation and methods by which the operating system could make improvements to meet targeted performance measures.

Importance of Productivity

Effectiveness of production and operation system may be viewed as the efficiency with which inputs are converted into outputs. The conversion efficiency can be gauged by ratio of the output to the inputs and is commonly known as productivity of the system. Productivity is the ratio of input facilities to the output of goods and services.

Output

Productivity = ————–

Input

= Goods or services

————————————-

Capital, manpower, materials, machines and land and building

The higher the productivity of the operating system, more efficient the operation function said to be. Management of operation system thus is essentially concerned with the management of productivity. Another way of looking at the concept of productivity is to look at the amount of waste generated in the system. If waste is unnecessary output and/or defective output from the system, then the productivity of the system can be improved by eliminating / minimizing the waste occurring in the system.

Policy formation in modern times has become a very complicated and time consuming phenomenon. Business enterprises now days want to plan their future strategies from the past performance. There are number of measures viz. Productivity, Profitability, rate of return etc. to illustrate the past performance. All these indicators are some sort of direct or indirect relationship between inputs and outputs factors. But none of the measures is able to determine or evaluate the overall performance of an enterprise. We shall be discussing measures of productivity in a little more detail in the following paragraphs.

The only way of raising the living standards of people is to increase productivity. Productivity can be increased by increasing output from each unit of input.

Concept of Productivity: In general sense, productivity is some relationship between inputs and outputs of an enterprise. It is quantitative relationship between what we produce and the resources used. The concept of productivity measurement is many sided. It can relate to every item/activity on which money is spent to get the final product some of the definitions given below explain the concept of productivity

Definition of Productivity:

- Productivity is a measure of how much input is produced to a given output i.e. it is ratio of output to input

- Productivity is the ratio between the amount produced and the amount of resources used in the course of production. The resources may be any combination of materials, machines, men and space.

- European productivity council defines “productivity is an attitude of mind. It is mentality of progress, of the constant improvement of that which exists. It is the certainty of progress, of the constant improvement of that which exists. It is the certainty of being able to do better than yesterday and continuously. It is the continual effort to apply new techniques and methods. It is the faith in human progress.”

- According to Peter Drucker, “productivity means a balance between all factors of production that will give the maximum output with the smallest efforts.”

- L.O generally takes productivity to mean. “The ratio between the volumes of output as measured by production indices the corresponding volume of labor input as measured by employment indices.”

- Organization of European Economic Community (OEEC) defines productivity as the ratio between the production of given commodity measured by volume and one or more of the corresponding input factors also measured by volume.

Thus there can be a number of measures indicating the level of performance corresponding to each input. In general sense, productivity is measure of how much input is required to produce a given output.

Importance of Productivity

The concept of productivity is of great significance for undeveloped and developing countries. In both the cases there are limited resources which should be used to get the maximum output i.e. there should be tendency to perform a job cheaper, safer, and in quicker ways. The aim should be optimum use of resources so as to provide maximum satisfaction with minimum efforts and expenditure. Productivity analyses and measures indicate the stages and situations where improvement in the working of inputs is possible to increase the output.

The productivity indicators can be used for different purposes viz. comparison of performance for various organizations, contribution of different input factors, bargaining with trade unions etc.

Factors affecting Productivity

All the factors which are related to input and output components of a production process are likely to affect productivity. These factors can be divided into 2 main categories, namely:

Category 1

Primary factors are effort and working capacity of an individual.

- Organization factors are related to the design and transformation process required to produce some item, the nature of training and other skill imported to workers to perform certain operations in a production process, control and various other incentives.

- Conventions and traditions of the organization e.g. activities of labor unions, medical facilities, worker and executive understanding etc.

Category II

- Factors related to output: research and development techniques, improvement in technology and efficient sales strategy of the organization will lead to improvement in output.

- Efficient use of input resources , better stores control , production control policy , maintenance of machines etc will minimize the cost of production

The factors listed in category I and II can be further divided into 4 major classes viz.

- Technological

- Managerial

- Labor, and

- External factors

The technological factors can increase the output per unit of input substantially. They can be defined in terms of technology employed, tools and raw material used.

The labor factors are characterized by the degree of skills of the works force, health, and attitude towards management, training and discipline

Managerial factors can be located in organizational structure, scheduling of work, financial management, layout innovation, personnel policies and practice work environment, material management etc.

External factors or innumerable and identifiable in the environment which an organization has to interact e.g., the power and transport facilities, tariffs and taxes etc have important bearing on the levels of productivity. Some of these factors are controllable and some are uncontrollable and demarcation should be made between the two.

Ways of increasing productivity

Productivity can be increased in a number of ways. It can be increased either by reducing the input for the same level of output or by increasing the output with the level of input or by combination of both. This can be achieved by elimination of waste , by using improved technology , better production design and management efforts there can be increase in productivity by reducing down time of maintenance , reduction in material inputs , better quality of goods , improved utilization of resources , reduction in working capital requirements , reduction in inventory size , improvement in man power skills through training etc . Output can be increased by better leadership management. When employees are better motivated output can be increased.

Decision making is a key factor which effects productivity. Better decisions obtained through educate and timely information system will improve effectiveness and efficiencies of the organization

Techniques to Improve Productivity

Productivity can be considerably improved by improving the performance of various factors affecting productivity. The measures to improve productivity can be:

Better planning and training of employees, improved jobs and communication and effective management through CPM/PERT methods.

- Use of time and motion studies to study and improve work performance. It enables to assess the quantum of work which can be used for planning and control.

- Better transportation and material handling systems.

- By providing work incentives and other benefits to workers.

- Workers involvement in decision making and working of organizations.

- Improvement in technology of production process and nature of raw material and the quality.

- Simplification, standardization and specialization techniques.

- Better and efficient utilization of resources at the disposal of the enterprise.

- Use of linear programming and other quantitative techniques for better decision making.

- ABC analysis to identify more important items and then apply inventory control to reduce capital investment.

- Value engineering to reduce material content by good design.

Measurement of Productivity

There are a number of ways to measure productivity. The main criterion of measuring productivity is:

- In term of input performance by calculating changes in output per unit of input

- On the basis of output performance by calculating changes in input per unit in output

Following are some of the measures in common use

Amount of output

Labor Productivity= ————————-

Amount of Labor

Where output can be measured in total quantity produced and labor can be measured in total manpower required to produce that output. Output and labor can also be measured in terms of their value in money units.

Turn

Capital Productivity =———————–

Capital employed

Profit

Profit Productivity = ———————–

Investment

Output

Energy Productivity =———————————

Quantity of energy used

A general measure of productivity can be defined as;

Output

Productivity = ———————————————-

Labor + Capital +Other inputs

Each kind of measure needs some specific kind of information. The appropriate measure can be selected on the basis of information available and the objective of investigation. In fact the measure of productivity indicates the performance of inputs namely labor and capital in an enterprise. Increase in output is not an indication of increase in productivity. Production is an absolute measure and productivity is a relative measure.

Each kind of measure needs some specific kind of information. The appropriate measure can be selected on the basis of information available and the objective of investigation. In fact the measure of productivity indicates the performance of inputs namely labor and capital in an enterprise. Increase in output is not an indication of increase in productivity. Production is an absolute measure and productivity is a relative measure.

X= (1-A)

Where I is the identity matrix and X is the matrix of estimated output (1-A) is known as Technology matrix. Input-Output analysis can be used to study the productivity of an enterprise. The index of productivity can be defined as:

Qi (1-Ai) Po

——————-

Qo (1-Ao) Po

Where Po Qo is the value of output in the base year and QiPo value in the current year based on base year, (1-Ai) is technology matrix in current year and (1-Ao) is technology matrix in base year.