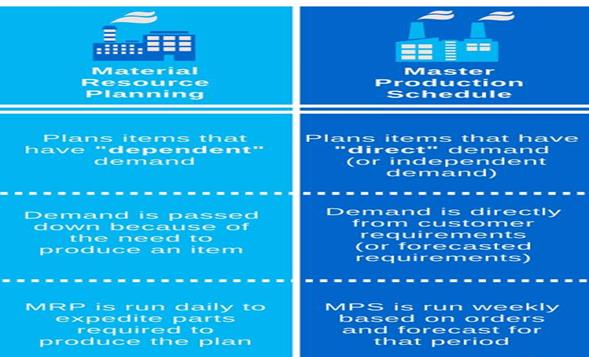

MPS stands for Master Production Schedule. A Master Production Schedule is the virtually exact same thing as MRP (Material Requirements Planning), the calculations are exactly the same, but there is one distinction.

MPS plans items that have “direct” demand, called independent demand. Independent Demand means that its demand comes from Sales Orders, Service Orders, or forecasts. The demand is directly from the customer requirements (or forecasted requirements).

MRP plans items that have “dependent” demand, demand that is passed down because of the need to produce an item.

So, if I make a pen, it has a cap, a barrel, a spring. and a refill. Based on the definition above, the pen is an MPS item. The cap, barrel, spring and refill are MRP items.

When producing pens, we would lay out an MPS production plan on a weekly basis. That finished good production plan would be based on the orders and forecast for that period. That would create a “Finished Good” plan which would not be changed (well, we tried not to change it). This plan was important because we needed to manage the production plan to group items together by color to minimize molding change over time. This level loaded our production plan for the week and created the demand required for the components to produce that finished good plan. MRP would be run daily to expedite any parts required to produce the plan.

So, why would a company run MPS separate from their MRP items? Many times the finished good plan is going to be laid out and not changed. So rather than run MPS items daily and deal with the change requests (every day, new orders come in and change the requirements; therefore, you get messages that need to be dealt with). This is particularly true of companies that need to plan like items together.

Master Production Schedule (MPS)

MPS operates within only one level of the BOM, While MRP can be utilized throughout all levels of a material’s BOM. If a MPS is run on a material, the necessary orders are planned at that level. Dependent requirements (if any) are placed on the next BOM level down, and then the process stops.

Main Idea : Master production scheduling (MPS) is a form of MRP that concentrates planning on the parts or products that have the great influence on company profits or which dominate the entire production process by taking critical resources. These items are marked as ‘A’ parts (MPS items) and are planned with extra attention. These items are selected for a separate MPS run that takes place before the MRP run. The MPS run is conducted without a BOM explosion so that the MRP controller can ensure that the Master schedule items (MSI) are correctly planned before the detailed MRP run takes place.

Material Requirements Planning (MRP)

A set of techniques that uses bill of material data, inventory data, and the master production schedule to calculate requirements for materials. It makes recommendations to release replenishment orders for material. Further, because it is time-phased, it makes recommendations to reschedule open orders when due dates and need dates are not in phase. Time-phased MRP begins with the items listed on the MPS and determines

- the quantity of all components and materials required to fabricate those items and

- the date that the components and material are required. Time-phased MRP is accomplished by exploding the bill of material, adjusting for inventory quantities on hand or on order, and offsetting the net requirements by the appropriate lead times.