Material Resource Planning (MRP) has become a centerpiece for all manufacturing system. The key to successful production and operations management in a manufacturing company is the balancing of requirements and capacities. It’s that simple and yet very challenging.

To understand it is essential and to practice it can be a lot of fun. Remember what you are trying to do: Meet the needs of your customers. How? By having the product available when it is wanted. In production management, we do this by knowing planning ahead to have the capacity available.

To begin with we shall define MRP.

Material requirements planning (MRP): A system of planning and scheduling the time phased materials requirement for production operations.

Planning for Materials Needs: In recent years material requirements planning systems have replaced reactive inventory systems in many organizations Managers using reactive systems ask,” What should I do now? “Whereas managers using planning systems look ahead and ask,” What will I be needing in the future? How much and when?

Improved customer service and other advantages come at a cost, however. They require a system for accurate inventory and product buildup information. They also require a realistic master production schedule (MPS) to specify when various quantities of end items will be completed.

Demand Dependency: Demand dependency is an important consideration in choosing between reactive and planning systems. Demand dependency is the degree to which the demand for some item is associated with the demand for another items. With independent demand, demand for one item is unrelated to the demand for others. In the dependent demand situation, if we know the demand for one item, we can deduce the demand for one or more related items.

Appling MRP as a Scheduling and Ordering System: MRP is a system of planning and scheduling the time phased materials requirements for production operations. As such, it is geared toward meeting the end item outputs prescribed in the master production schedule.

MRP Objectives and Methods: MRP provides the following:

- Inventory reduction: MRP determines how many of a component is needed and when, in order to meet the master schedule.

- Reduction in production and delivery lead times: MRP identifies materials and components quantities, timings, availabilities, and procurement and production actions required to meet delivery dealings.

- Realistic commitments: Realistic delivery promises can enhance customer satisfaction. By using MRP, production can give marketing timely information about likely delivery times to prospective customers.

- Increased efficiency: MRP provides close coordination among various work centers as products progress through the process

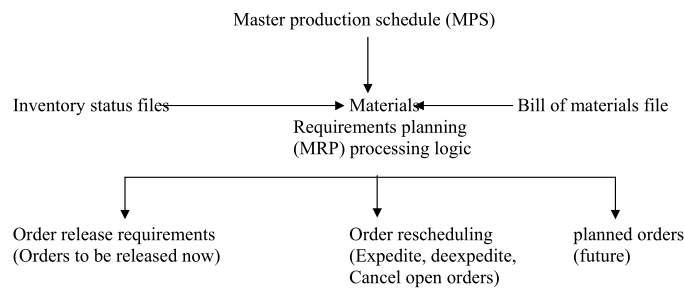

MRP System Components: Shows the basic components of an MRP system.

- Master Production Schedule (MPS): The MPS is initially developed from firm customer orders or from forecasts of demand before the MRP system. Designed to meet market demand, the MPS identifies the quantity of each end product (end item) and when it needs to be produced during each future period in the production planning horizon.

- Bill of Materials (BOM): The BOM identifies how each end product is manufactured, specifying all subcomponents items, their sequence of buildup, their quantity in each finished unit, and the work centers performing the buildup sequence.

- Inventory Status File: The MRP system must retain an up to date file of the inventory status of each item in the product structure. This file provides accurate information about the availability of every items controlled by the MRP system which can then maintain an accurate accounting of all inventory transaction, both actual and planned.

- The MRP Processing Logic: The MRP processing logic accepts the master schedule and determines the components schedules and determines the components schedules for successively lower level items of the product structures. It calculates for each item in each product structure and for each time period (typically one week) in the planning horizon how many of that item are needed (gross requirements), how many units from inventory are already available, the net quantity that must be planned on receiving in new shipments (planned order receipts), and when orders for the new shipments must be placed (planned order releases) so that all materials arrive just when needed.

- The MRP Computational Procedure: The MRP computational procedure uses the input information to calculate the current records for each component and item.

- Information Processing Sequence: The MRP processing logic is applied first to the high level items (end products) in the product structure, then to the items on the next lower level.

- Indented Bill of Materials: To do its level by level calculations, the MRP processing logic obviously needs information about an end item’s relationship to all its subcomponents.

- Product Explosion: To create a parent item we often need multiple units of a lower level item.

- Low Level Coding: Often a single item is in the product structure of several end items, or it exists in several levels of one product structure.

Using MRP Outputs for Materials Decision: MRP merely indicates what actions are needed to meet the MPS goal; now management must act to “Make things happen” to cause (control) the productive system to execute so that management gets the results it wants.

Keeping MRP Current in a Changing Environment: MRP is not state; it is responsive to new job orders from customers and current shop conditions, as well as changes anticipated for the future.

- Pegging: The process of tracing through the MRP records and all levels in the product structure to identify how changes in the records of one component will affect the records of other components.

- Cycle counting: Counting on hand inventories at regular intervals to verify inventory quantities shown in the MRP.

- Regenerative method: A procedure, used at regular intervals, to update the MRP by completely reprocessing the entire set of information and recreating the entire MRP.

- Time fence: A designated length of time that must pass without changing the MPS, to stabilize the MRP system; afterward, the MPS is allowed to change.