Periodic lot sizing procedures are namely – the ‘daily lot sizing’, ‘monthly lot sizing’ and ‘weekly lot sizing’ (in fact you can decide the period of the lot size in lot sizing customizing). The requirements that lie in a given period are clubbed together and the availability date for the procurement proposals would be the start date of the first requirement in the period. The standard configuration of lot sizes puts the requirements for periodic lot sizing at the start of the first requirement in the period, but you can have it set to the end of the period also.

Availability Date = Start of the period or

Availability Date = End of the period

And if the lot sizing procedure is “weekly”, SAP MRP will consider all the demands for the week and all the receipts for the week and place a weekly proposal (planned order or purchase requisition). The weekly proposal can be put at the start of the week or at the end of the week as the configuration in the lot sizing procedure.

Optimum Lot Sizing Procedures

Whereas there is a less famous procedure for lot sizing called the ‘optimum lot sizing procedures’ which deals with the concept of economical lot sizing, namely the ‘Groff lot sizing method’ and ‘part period balancing’. These procedures take in to account the costs of the procurement and other involved cost elements.

Other tools in lot sizing procedures

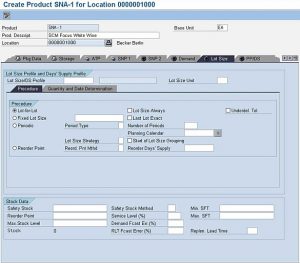

You can use the below listed tools along the lot sizing procedures selected in the MRP 1 view of the material master. It should also be noted that not all the tools can be used along with all the lot sizing procedures.

Minimum lot size – When the minimum lot size is 80 and the required quantity is 100, the system creates a requirement proposal for a quantity of 100 Units, to cover the shortages. This can be used with almost all the lot sizing procedures.

Maximum lot size – If the required quantity through a demand is 120 kg, then the system will create two planned orders of 80 kg & 40 kg {if the Plant/Storage location stock for that material is Zero}

If the procurement qty is 140 kg, and the Maximum lot is 80 kg and minimum is 15 kg, then the system will create 2 planned orders of 80 kg & 60 kg. {If the Plant/Storage location stock for that material is Zero}

If the procurement qty is 85 kg, and the Maximum lot is 80 kg and minimum is 15 kg, then the system will create 2 planned orders of 80 kg & 15 kg {if the Plant/Storage location stock for that material is Zero}.

This can be used with almost all the lot sizing procedures.

Fixed Lot Size – In this procedure, the lot sizes are fixed and the procurement proposals are created for the given fixed quantity.

If the required Quantity through demand/demands is 120 and the fixed lot size is 80, then the system will create 2 planned orders with one planned order of quantity 80 an the other planned order of Qty 80 {if the Plant/Storage location stock for that material is Zero}.

Rounding Values – If the Rounding Value is 20 units, the procurement quantity is 70 units, and the minimum lot size is 15 units, then the system will always round up the planned order to a multiple of 20 units, specifying the rounding to a quantity of 20 Units.

You would have already noticed that the minimum lot size, in the above example, really did not play any role, but if the procurement quantity, for example, would have been 13 units, then the system would have created one planned order of 20 units, which covers both the minimum lot size and the rounding requirements.

One more example would be, if we don’t consider the Min/Max Lot size and the procurement quantity is 70, then the system would just create one planned order of 80 to round off to 20 {if the Plant/Storage location stock for that material is Zero}.

Again the rounding value tool in the MRP 1 view can be used with almost all the lot sizing procedures.

Rounding Profile – The static rounding value method may not satisfy all the business cases, where a given rounding value is used and the procurement proposals are rounding to that value. There may be situations where the rounding value may change according to the size of the procurement proposal; this is where the concept of rounding profile may help you.

Rounding Profile allows you to enter a procurement quantity and the corresponding rounded value that is applicable if the procurement quantities. You may configure the system to have a rounded value of 10 units, if the procurement quantity is at least 1 unit and a rounded value of 100 units, if the procurement quantity reaches 70 units. The transaction code to configure is OWD1. The Rounding profile configuration screen would look something as below. The Rounding Profile configured is named as Z001”.

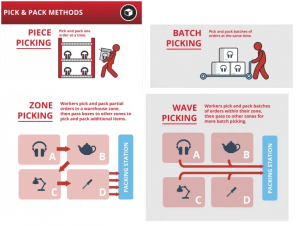

There are a number of dimensions to the picking process. These include how and when the orders are presented, how the actual items are picked and the equipment required. There can be many interrelationships and many options. For example, if we decide on a picker-to-goods operation this can either be done by, for example, picking individual orders, batch or cluster picking, utilizing trolleys or pallet trucks and a choice of paper, voice or scanning.

A picking operation may require full-pallet picks, pallet-layer picks, outer-carton picks, inner-carton picks or individual-item picks. In most cases the warehouse will be required to pick a combination of the above and, at times, a combination even on the same order. Besides ABC Analysis and Order profiling, basic techniques such as profiling, slotting, pick-route planning, pick-face sizing, proper equipment selection and documented processes will all help to enhance pick efficiency without having to introduce technology and automation in the short term.

Companies are likely to operate a number of different order-picking strategies and techniques depending on the nature of the product, the quantity of items to be picked and the size of order. There are usually four types of pick requirement within a warehouse. However, they do not always occur individually and can be included on the same order. These are as follows:

- piece, unit, item or broken-case pick

- full-case or carton pick

- layer pick

- full-pallet pick

Pick strategies can be split into three categories. These are

- picker to goods

- goods to picker

- automated picking

Picker to Goods

The majority of warehouses continue to operate with minimal automation and therefore picker-to-goods operations prevail.

Pick to order – The picker takes one order and travels through the warehouse either on foot with a cage or trolley or with a pallet or fork truck, collecting items until the whole order is picked. Orders can be for individual items, full cartons or even full pallets. The picker follows a route designated by reading a paper pick list, reading instructions on a radio data terminal or following voice commands.

All order lines are picked in sequence for a specific customer order. Depending on the size of the items, these will be stored on shelf locations, in carousels or on flow racks. Full cartons can be stored on pallets in pick locations or in flow racking. The advantage of picking individual orders is the minimum amount of handling involved. This remains the most common method of picking. However, orders with multiple SKUs and long distances between picks can be very labor intensive. There is normally a requirement for a second person to check the order before it is dispatched.

Cluster picking – In order to reduce overall travel time, operators can take a number of orders out into the warehouse and pick into individual compartments on their trolleys or cages. Some operations will utilize powered pallet trucks that can carry two pallets at a time or utilize tugs or tractors that can move multiple pallets through the picking aisles. Cluster picking can also be used with conveyors, where a tote diverts into a pick zone. As the tote passes a barcode reader its unique ID is read and all the picks for the current tote are displayed on the individual pick-to-light terminals.

Zone Picking – In zone picking, products are picked from defined areas in the warehouse and each picker is assigned to a specific zone or zones and only picks items from within those zones. The level of activity will determine the number of zones allocated to each picker. Orders are moved from one zone to the next as each zone completes its pick. This movement can be undertaken by a cage, trolley or pallet being passed from one operator to another but is more commonly done by conveyor. The conveyors may be powered or use rollers or gravity to move the cartons or totes between the zones.

The volume of orders sent to each zone needs to be controlled so that each sector has an equivalent amount of picks. The potential for bottlenecks can be high with staff having to wait for orders to arrive. Zones are usually sized to accommodate enough picks for one or two order pickers. A picker may look after two zones or more if the volumes are reduced on a particular day. Zone picking can be effective in operations with large numbers of SKUs, multiple orders and low to moderate picks per order.

Wave Picking – In wave picking, orders are released at specific times during the day. This can be hourly or morning or afternoon. The idea is to associate them with vehicle departures, replenishment cycles, shift changes, etc. Orders can be released at different times to different zones based on how long it takes to pick the orders.

Batch Picking – Batch picking is when one picker picks a group, or batch, of orders at the same time, one SKU at a time. This is advantageous when there are multiple orders with the same SKU. When that occurs, the order picker only needs to travel to the pick location for that specific SKU once, in order to fill the multiple orders.

The main advantage for choosing this method is reduced travel time, which increases productivity. Batch picking is often used when the typical order profile has only a few SKUs (under four) and the SKUs physical dimensions are relatively small. Just as in zone picking, batch picking requires only one order scheduling window per picking shift.

Zone-Batch Picking – This is a combination of methods in that pickers are assigned a zone, just like traditional zone picking, however they are also directed to batch pick within their zone. Since both zone picking and batch picking have a scheduling window, then zone-batch picking does too.

Zone-Wave Picking – Zone-Wave Picking is a combination of methods in that pickers are assigned a zone and each picker within their zone picks all of the SKUs for all orders that are stocked in their zone, one order at a time with one scheduling window per shift.

Zone-Batch-Wave Picking – The most complex combination of all of the order picking methodologies. Each picker is assigned a zone and picks all SKUs for orders stocked in the assigned zone. Additionally, the picker picks more than one SKU at a time and there are multiple scheduling windows per shift.

Goods to Picker

Significant benefits can be realized with the use of a goods-to-person system. Even though there are many variations on how a system can be configured, most of the designs allow the following benefits,

- Ergonomic workstations: The pick stations can be designed for employee comfort. Working heights, range of motion and environment (lighting, temperature) can be optimized for the employee.

- Speed in order selection: The pick station design allows high worker productivity. Since there is little or no travel time and the item to be picked is ergonomically served to the worker, high rates of order selection are achieved.

- Accuracy: Order picking using a goods-to-person station is more accurate because operators are typically handling one SKU at a time, making errors less likely.

- Decoupled workstations: Staff can work in parallel, unaffected by each other. Stations can be opened and closed according to business volume on a particular shift of operation.

- High-utilization workstations: Work flows into the pick station smoothly and consistently. Order pickers are highly utilized, since they do not need to wait for work.

- Sequencing: When building a customer order, a precise sequence of SKUs can be achieved. For example, items can be presented to the order selector by weight (heavy to light). Or, in another example, orders can be built in sequence by family group.

- Order profile: The system is not affected by changes in order profile. For example, single-item orders and multi-item orders are accommodated with equal efficiency.

Examples of goods-to-picker systems are listed below.

Compact picking system – The goods-to-picker-based compact picking system is ideal for slow-moving products in retail and wholesale warehouses. It is also cost effective for warehouses handling parts and components for sectors such as the automotive industry which have a large range of SKUs and very high service levels. Product is retrieved from the storage area and taken by conveyor to the operator’s workstation. There it is consolidated with other items and placed in a shipping carton for dispatch.

Order distribution system – An order distribution system is ideal for business processes where a large number of order lines are fulfilled from a relatively small number of SKUs. Totes or cartons of single-line products are transported to operators who distribute goods into order totes controlled by put-to-light displays. This concept works efficiently in mail order and e-commerce sectors. In both the above operations the workstation plays a major part in the overall system.

Moreover, the picking stations feature optimal workplace lighting, large and comfortable operating controls and acknowledge buttons. Height- and rake-adjustable human–machine interaction (HMI) screens are also part of the ergonomic equipment package.

The HMI display provides the visual management of the pick processes. Its multicolor, high-resolution screen displays simple, intuitively under-stood symbols for article volumes, photos of the products to be picked and a 3D description of the positioning of the picks in the order carton. All these features contribute to accurate, safe order picking with virtually no error rates. As optional additional verification, volume weighing can be integrated into each picking station.

Automated Picking

The requirement for increased speed, accuracy and productivity has pointed managers towards automation as a realistic option in today’s competitive automated equipment market. A high-volume item pick operation is an area where automation can have a high impact. An operation where the dispatch of upwards of 3,000 cartons per day is worth a consideration in terms of automation. Vanderlande Industries introduced a new, revolutionary automated case-picking (ACP) system in 2009, which they claim lowers the costs per case handled by 40 per cent compared with a manual case-picking operation. The system is especially aimed at food retailers, who require very high system capacity to handle a large product range.

In this system, pallets arriving at the warehouse or coming from bulk storage are automatically de-palletized layer by layer. Each pallet layer is stored on a tray in a mini-load AS/RS system. Storing pallet layers instead of individual cartons significantly reduces the number of crane movements and therefore the number of AS/RS systems required to handle the workload. Hence, the ACP system requires a significantly lower initial investment and reduces order picking costs per case handled by 40 per cent compared with a manual operation. The ACP system has a very short payback time, less than four years. The new ACP system also secures stock availability in the pick face and ensures short order processing time, improving service level to,

- elimination of manual handling

- reduction in accidents

- ability to cope with hazardous/harsh environments such as refrigerated storage

- integration

- coordination of product flows, avoiding bottlenecks

- constant performance levels

- continuous review

Never automate a bad or broken process. Always ensure that the warehouse operation is working efficiently without the use of technology.

Automation requires a great deal of preparation and time spent on design, evaluation and implementation. Automation can provide significant improvements in productivity and accuracy – but it can also prove to be the wrong solution.

The disadvantages of automation are,

- High opportunity cost

- High investment costs such as building, equipment, information technology

- System failure

- Standardized unit loads are required

- Anomalies are not accepted and need to be handled separately

- More quality control is required on intake

- High cost of disposal of equipment

- Lack of flexibility

Inventory picking Metrics

- Average number of units picked – How much product is being picked every day? Every night? What is the total picked throughout the cycle? And what do you do with these numbers to maximize productivity?

- Average number of units put away – The average number of units put away is a useful metric for the receiving team to see how they are performing putting away products received from suppliers.

Guidelines for optimizing inventory picking

- Ensure that your production schedule allows for 100% availability of inventory — You must have a minimum level of inventory per day, as well as an effective communication procedure for when you might be running low on an item.

- Plan your picking routes carefully —Warehouse’s picking routes improve productivity and should be reviewed to establish routes that eliminate backtracking, which can cause major slowdowns. Also, keep in touch with your pickers to better understand the factors that may be slowing them down.

- Implement velocity-based slotting —Based off of its specific velocity, a product should be sitting in a “prime slot,” for quick pick up.

- Invest in smart automation — Automation provides accurate and time-efficient picking, and should be implemented as applicable.

- Keep records of error data —Keep thorough records of all error data, including missed time targets, and properly analyze it to get a better idea of who is to blame.

- Slot SKUs by Zone or Technology

- Slot Inventory by SKU Velocity

- Conduct ABC Analysis/Order Profiling – Collect data to understand how efficiently inventory is managed.

Augmented Reality in Picking

‘Augmented vision’ can be highly useful for various industries, especially for logistics and warehouse management. Of all the tasks associated with warehouse management, the area where AR enhancements can be most effective and promising is item picking.

Navigation – The way AR navigation works is quite straightforward. First, an employee uses smart glasses or a smartphone to open a list of the items to pick from. They can do it in less than a minute by simply uploading the list from the WMS integrated with the app. Software then analyzes the list along with reading the up-to-date warehouse layout data, and creates the most convenient and fast route for collecting all items.

Locating an item – After an employee arrives at the necessary location, the app automatically locates the item by pointing at it. Knowing the precise layout of your warehouse as well as the standard item placement in it augmented reality software analyzes the item code group in the list.

Item data synchronization – After the AR app completes scanning of an item’s barcode, it communicates with the integrated systems (WMS, CRM, etc.) and pulls in all information about the item.