Improvement comes from simplifying processes and procedures. In order to improve efficiency and reduce cost within the warehouse operation it very important to get all warehouse processes to be aligned. Although warehouses differ in terms of size, type, function, ownership and location yet the fundamental processes remain the same and are critical to study for each manager. These processes include pre-receipt, receiving, put-away, storage, picking, replenishment, value-adding services and dispatch. Ensuring that the correct processes are in place and operating optimally, companies not only improves accuracy and efficiency but also take advantage of the new technology available. Picking process is one of the most important warehouse processes as it is most labor and cost intensive process and has a direct impact on customer service. We must also recognize the importance of pre-receipt and the receiving process as receiving the wrong products or putting products in incorrect locations can result in errors just as easily as can picking the wrong item.

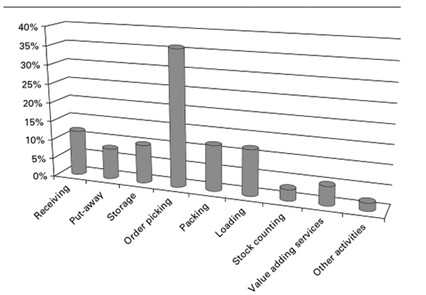

Figure 3.1 below shows each warehouse activity as a percentage of cost, emphasizing the importance of the pick, pack and dispatch operation. The figure may vary significantly depending on the type of operation.

For example, companies which are under pressure to speed up throughput are likely to use concepts such as cross docking, thus reducing the amount of time spent on put-away, picking and retrieval.

Figure 3.1: Warehouse activities as a percentage of total cost