Customers are looking for value. They are also increasingly looking for responsiveness—the desire for more customization and smaller batch sizes has led to faster turnarounds, smaller inventory levels and more just in time (JIT) delivery requirements.

As per the Supply Chain Digest, a hybrid supply chain is both “Lean” and “Agile” or “Leagile”. This can take one of several approaches1:

- Using make-to-stock/lean strategies for high volume, stable demand products, and make-to-order/agile for everything else

- Have flexible production capacity to meet surges in demand or unexpected requirements

- Use of postponement strategies, where “platform” products are made to forecast, and then final assembly and configuration done upon final customer order

In most cases it is not an “either, or” situation.

- Lean Systems are necessary in order to do things as efficiently as possible – to add value while identifying and eliminating waste.

- Agility and Responsiveness is necessary to be able to quickly react to ever-changing customer demands with speed and flexibility.

The bottom line? Clients don’t want you to stop eliminating waste just because they need things customized and need them quickly.

A hybrid supply chain strategy may be appropriate for a company attempting to become a “mass customizer”—producing progressively smaller batch sizes (sometimes as little as one item) specific to customers’ sometimes unique needs.

A Lean supply chain focuses on adding value for customers, while identifying and eliminating waste—anything that doesn’t add that value. Being agile and responsive, on the other hand, implies that your supply chain can handle unpredictability—and a constant stream of new, innovative products—with speed and flexibility.

An agile strategy uses a wait-and-see approach to customer demand by not committing to the final product until actual demand becomes known (also referred to as postponement). For example, this might involve the subassembly of components into modules in a lower-cost process, with final assembly done close to the point of demand in order to localize the product.

An agile supply chain must be responsive to actual demand, and capable of using information as a substitute (to some degree) for inventory through collaboration and integration with key customers and suppliers.

Either, Or, or Both

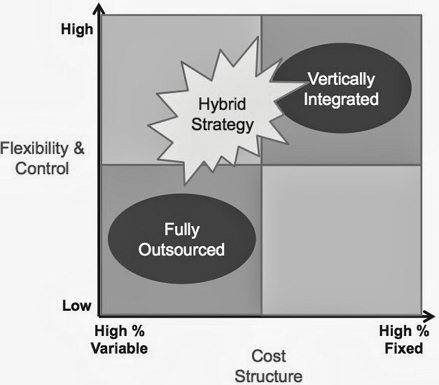

On some occasions, either an agile or a Lean strategy might be appropriate for a supply chain. But many companies will probably face situations where a hybrid strategy is a better fit. If so, they need to carefully plan and execute the combined strategy with excellence, which is often easier said than done because it involves a lot of moving parts. As in so many aspects of supply chain and operations management, there is more than one way to accomplish this goal.

One example of a company using a hybrid strategy in its supply chain is Zara, a Spanish fashion designer and retailer. Zara directly manufactures most of the products it designs and sells, and performs activities such as cutting, dying, labeling, and packaging in-house to gain economies of scale. A network of dedicated subcontractors performs other finishing operations that cannot be completed in-house.

As a result, Zara has a supply chain that is not only agile and flexible, but incorporates many Lean characteristics into its processes.

Some semiconductor manufacturers incorporate a hybrid strategy using a flexible manufacturing and distribution model. Subcontractors perform distinct manufacturing processes at separate physical locations. This hybrid approach taps a virtual network of manufacturing partners and requires responsive, flexible, and information-driven sourcing, manufacturing, and distribution functions—in many ways, the opposite of Zara’s strategy of shifting processes in-house.

Many organizations can find some form of hybrid supply chain that works well for them. In today’s ever-changing, volatile, and competitive global economy, it may often be in a company’s best interest to operate a supply chain that is both Lean and agile.

Which System is Best?

The answer to that question, of course, is that “it depends.” To demonstrate the truth of that statement, the researchers worked with a manufacturer of components for the HVAC industry. The company currently employs a lean strategy, manufacturing in Mexico and distributing from two U.S. distribution centers.

Based on actual operating data, the researchers then model what supply chain performance would look like if either an agile or hybrid (postponement) strategy was embraced. As always in this type of work, a number of assumptions were necessary to create the model, but in this case they do not seem to make the analysis too far removed from the real world, as is often the case.