The various forms of logistics management are described as follows:

Return Logistics (Reverse Logistics)

In order to increase the sales as well as the market share, many companies advertise that their goods will perform well over a period of time. The customer is, therefore, led to believe that in case he buys the product of that company, he is assured of satisfactory performance of the product.

But at the same time, it is very much obvious that the company cannot assure the satisfactory performance of each and every of its product which is sold in the market. Few of the products sold may not perform as claimed over the specific period of time.

Such products need to be brought back by the company to confirm good customer service. Product recall is a critical competency resulting from increasingly rigid quality standards product expiration dating responsibility for hazardous consequences. The company has, therefore, to take into account the defective goods that would be returned while framing the total logistical system network and calculating the total cost of such a system of network.

Incorporating the goods returned in the total logistical systems network and cost is called as Return Logistics. Return Logistics requirement’ also result from the increasing number of laws prohibiting random scrapping and disposal on one hand, while encouraging recycling of waste such as beverage containers, packaging materials, etc.

The most significant aspect of return logistical operation is the need for maximum control when a potential health liability exists such as a contaminated drug in the market is extremely dangerous and the company has to recall all the stock of contaminated drug.

Military Logistics

Military logistics is the art and science of planning and carrying out the movement and maintenance of military forces. In its most comprehensive sense, it is those aspects or military operations that deal with.

- Design, development, acquisition, storage, distribution, maintenance, evacuation, and disposition of material,

- evacuation, and hospitalization of personnel,

- Acquisition or construction, maintenance, operation, and disposition of facilities.

Third Party Logistics (3PL)

3PL or Third Party Logistics describes businesses that provide one or many of a variety of logistics related services. Types of services would include public warehousing, contract warehousing, transportation management, distribution management, freight consolidation.

A 3PL provider may take over all receiving, storage, value added, shipping, and transportation responsibilities for a client and conduct them in the 3PL’s warehouse using the 3PLs equipment and employees or may manage one or all of these functions in the clients facility using the clients equipment, or anything combination of the above.

3PL can be defined as the “Business of proposing physical distribution reforms to a client and undertaking comprehensive physical distribution services.”

The growing demand for 3PL can be attributed to both demand & supply side factors.

- faced with deregulation & growing competition, transport companies are seeking new business opportunities, &

- Clients are seeking to outsource their operations cut costs & focus resources on core businesses.

Fourth Party Logistics

Traditionally, suppliers and big corporations have been meeting the demands by increased inventory, speedier transportation solutions posting on-site service engineers and many times employing a third party service provider.

Today they need to meet increased levels of services due to e-procurement, complete supply visibility, virtual inventory management and requisite integrating technology. Now corporations are outsourcing their entire set of supply chain process from a single design, make and run integrated comprehensive supply chain solutions.

This evolution in supply chain outsourcing is called Fourth Party Logistics – the aim being to provide maximum overall benefit.

Thus a fourth party logistics provider is a supply chain integrator that assembles and manages the resources, capabilities and technology of its own organization with those of complementary service provider to deliver a comprehensive supply chain solution.

It leverages the competencies of third party logistics providers and business process managers to deliver a supply chain solution through a centralized point of contact. As the fourth party logistics provider caters to multiple clients, the investment is spread across clients-thus taking the advantage of economies of scale.

Inbound Logistics

Creation of value in a conversion process heavily depends on availability of inputs on time. Making available these inputs on time at point of use at minimum cost is the essence of Inbound Logistics. All the activities of a procurement performance cycle come under the scope of Inbound Logistics. Scope of Inbound Logistics management covers transportation during procurement operation, storage, handling if any and overall management of inventory of inputs.

Several activities or tasks are required to facilitate an orderly flow of materials, parts or finished inventory into a Manufacturing complex as – sourcing, order placement and expediting, transportation, receiving and storage. Overall, procurement operations are called inbound logistics. Inbound logistics have potential avenues for reducing systems costs. Delivery time, size of shipment, method of transport & value of products involved are different from those of physical distribution cycles. Normally delivery is large as a low cost transportation mode is chosen.

Outbound Logistics

Value added goods are to be made available in the market for customers to perceive value. Finished goods are to be distributed through the network of warehouses and supply lines to reach the consumer through retailers’ shops in the market.

During conversion value is added to the raw materials and as a result value of the inventory in this case is very high unlike inputs. The size of shipment, modes, of transport and delivery time is different as compared to inputs. Activities of shipment, distribution performance cycle come under the scope of Outbound Logistics management as- order, transportation, warehousing, packaging, handling etc.

Aggregate Levels

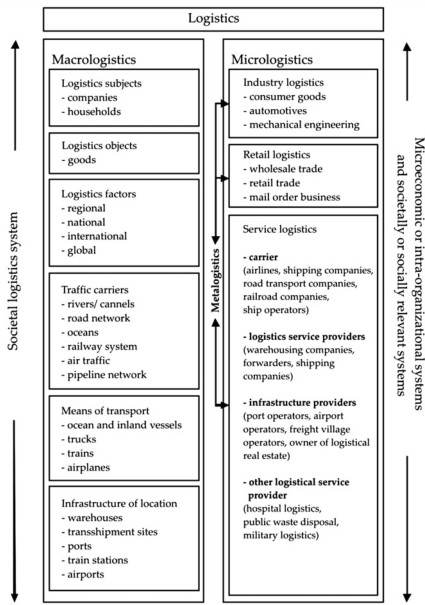

The now all-encompassing process of the transformation of goods from the source to the drain can also be described in national economic terms. Referring to the different aggregate levels in economics, a distinction has to be drawn between macro logistics, micro logistics, and – deriving from these two – meta logistics management.

Macro logistics on the one hand describes the traffic system and, on the other hand, the suitable infrastructure for the logistical core functions of warehousing and transshipment. Thus, macro logistics represents the macroeconomic perspective.

Micro logistics describes microeconomic systems with logistical functions which in most cases are characterized by the respective sector. From a shipping agent’s viewpoint, industrial logistics is different from retail logistics in that they each cater their logistical performance to varying time standards and to the respective differences in the shipper’s and recipient’s supply and demand behavior. The logistical service is a secondary service for the consignor, i.e. it is not the company’s main purpose.

In service logistics, the logistical operation is a primary service, i.e. the actual object of the company. Depending on the kind of services provided by the respective companies, we can distinguish between carriers, logistics service providers in the narrow sense (forwarders, shipping companies etc.), and infrastructure providers (warehousing service providers). Furthermore, societal or social systems such as hospital logistics management or public waste disposal can be subsumed under the term micrologistics.

Metalogistics describes every kind of institutional or functional cooperation between independent organizations within micrologistics in order to enable logistical performance. These co-operations may be established, for instance, between industrial and commercial companies to facilitate the joint organization of warehousing and the supply of final customers, between logistics service providers to build up a nation-wide distribution network covering all regions, or between different traffic carriers (railway, inland vessel, road, air traffic)