Means of escape is the structural means whereby a safe route is provided for people to travel from any point in a building or structure to a place of safety without assistance. Place of safety is a place in which a person is no longer in danger from fire. The occupant capacity is the maximum number of people who can be safely accommodated at the venue. In the case of standing areas at longer events there is a need to take into account ‘sitting down’ space for the audience and freedom of movement for access to toilets and refreshment facilities.

In areas where seating is provided, the major part of the occupant capacity will be determined by the number of seats available. However, in other cases, a calculation will need to be made and this is based on each person occupying an area of 0.5 m2. The maximum number of people who can be accommodated can therefore be calculated by dividing the total area available to the audience (in m2) by 0.5.

General principles for means of escape

- People should be able to walk to safety along a clearly recognisable route by their own unaided efforts regardless of where a fire may break out at the venue.

- When evacuation is necessary, people often try to leave the way they entered.

- exits are suitable and sufficient in size and number;

- exits are distributed so that people can turn their back on any fire which may occur;

- exits and exit routes are clearly indicated; and

- escape routes are adequately lit .

Outdoor venues such as parks, fields and gardens of stately homes will normally have boundary fences at their perimeters. To provide means of escape which will allow for an orderly evacuation to take place, ensure that

- the number and size of exits in the fences, etc, are sufficient for the number of people present and are distributed around the perimeter;

- exits and gateways are unlocked and staffed by stewards throughout the event; and

- all exits and gateways are clearly indicated by suitable signs which are illuminated if necessary.

Fire Triangle

To understand how fire extinguishers work, you need to understand a little about fire. Fire is a very rapid chemical reaction between oxygen and a combustible material, which results in the release of heat, light, flames, and smoke. For fire to exist, the following four elements must be present at the same time:

- Enough oxygen to sustain combustion.

- Enough heat to raise the material to its ignition temperature.

- Some sort of fuel or combustible material.

The chemical reaction that is fire.

Classification of Fires

Fires are classified in accordance with BS EN 2- 1992 and are defined as follows

- Class A fires- fires involving solid materials, usually of an organic nature, in which combustion normally takes place with the formation of glowing embers. These are ordinary combustibles such as wood.

- paper, cloth, rubber and most plastics.

- Class B fires- fires involving liquids or liquefiable solids and gases, such as gasoline, diesel, paint and paint thinners, and propane.

- Class C fires- These are energized electrical equipment such as computers, power tools, hair dryers and curling irons, and electrical boxes and panels

- Class D fires- fires involving metals. These are combustible metals such as magnesium (found in mag wheels), titanium, potassium, and sodium. Explosions may occur if regular extinguishers or water is used so a dry powder is used to extinguish these fires.

- Class K – These are cooking oils and fats such as vegetable and animal fats. These fires need a wet material to stick to the fire and smother it.

Fire -fighting equipment

All venues should be provided with appropriate portable or hand-held fire -fighting equipment and this provision should be determined at the planning stage in consultation with the local authority and fire authority.

Fire extinguishers – If portable fire extinguishers are installed, they should conform to BS EN 3- 1996 and be colour coded in accordance with BS 7863- 1996 and BS 5306- 1985. Portable fire extinguishers apply an extinguishing agent that will either cool burning fuel, displace or remove oxygen, or stop the chemical reaction so a fire cannot continue to burn. When the handle of an extinguisher is compressed, agent is expelled out the nozzle.

Hose reels – If hose reels are installed they should be located where they are conspicuous and always accessible. The hose should comply with Type 1 hose specified in BS 3169- 1986 and hose reel installations should conform with BS 5306- Part 1 1976 and BS EN 671- Part 1 1995.

Fire Detectors and Alarms: Fire detection and alarm systems are installed in Cargo area, accommodation, deck areas, and machinery spaces along with alarm system to notify any outbreak of fire or smoke at the earliest.

Fire fighter’s gear – fire resistant outer suit, inner lining suit, inner and outer gloves, woolen socks, fire resistant shoes, helmet with or without headlight and communication system, breathing apparatus, water hoses, valves, nozzles and IR camera etc., fire department’s vehicle mounted firefighting equipment

Installed firefighting system – fire main water supply network, hydrant, sprinkler automatic or manual, emergency fuel and electric cut off system, fixed firefighting system such as carbon dioxide, foam and powder type etc., portable generators and pumps.

Communication equipment – walkie-talkie, radio, broadcasts, land line telephone, sound powered telephone, cell or mobile phone and voice pipe etc.

Fire blankets – Fire blankets are suitable for some types of fire. They are classified in BS 6575- 1985 and are described as

- Light duty- these are suitable for dealing with small fires in containers of cooking fat or oils and fires in clothing.

- Heavy duty- these are for industrial use where there is a need for the blanket to resist penetration by molten materials.

Types of fire extinguisher

Fire extinguishers work by removing one of the three elements from the fire triangle thus stopping fire from growing. There are as many different types of extinguishers on the market as there are different types of extinguishing agents. The various types of extinguishers are

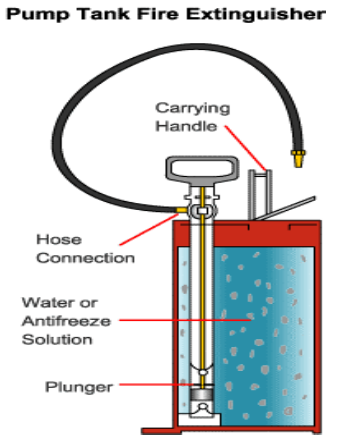

- Water Fire Extinguishers: The cheapest and most widely used fire extinguishers. Used for Class A fires. Not suitable for Class B (Liquid) fires, or where electricity is involved. Pressurized water extinguishers are the simplest extinguishers on the market. They work by removing the heat from the fire triangle. Water extinguishers are indicated for all class A fires. Water extinguishers cannot be used on class B, C, D or K type fires. The pressurizing handle on the top of the unit usually can identify these extinguishers.

- Foam Fire Extinguishers: More expensive than water, but more versatile. Used for Classes A & B fires. Foam spray extinguishers are not recommended for fires involving electricity, but are safer than water if inadvertently sprayed onto live electrical apparatus.

- Dry Powder Fire Extinguishers: Often termed the ‘multi-purpose’ extinguisher, as it can be used on classes A, B & C fires. Best for running liquid fires (Class B). Will efficiently extinguish Class C gas fires, but beware, it can be dangerous to extinguish a gas fire without first isolating the gas supply. Special powders are available for class D metal fires. when used indoors, powder can obscure vision or damage goods and machinery. It is also very messy.

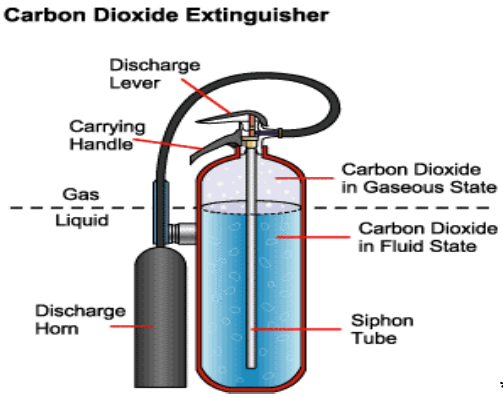

- CO2 Fire Extinguishers: Carbon Dioxide is ideal for fires involving electrical apparatus, and will also extinguish class B liquid fires, but has NO POST FIRE SECURITY and the fire could re-ignite. These extinguishers use compressed CO2 gas to displace the oxygen from the fire. Without oxygen, the fire triangle is broken and fire cannot continue. They are indicated for Class B and class C type fires. The large horn at the end of the nozzle usually can identify these extinguishers.

- Wet chemical – Specialist extinguisher for class F fires. The Wet Chemical Extinguisher extinguishes a fire by removing heat and preventing barriers between oxygen and fuel so a fire cannot be re-ignited.

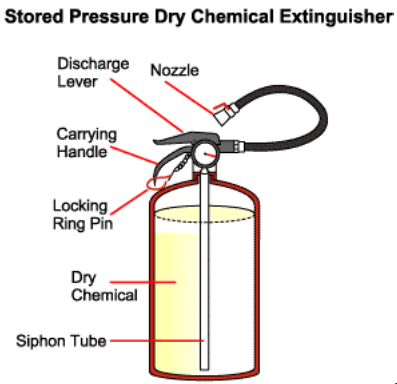

- Dry Chemical – These extinguishers use an extremely fine chemical to both displace oxygen and absorb heat to disrupt the fire triangle. The indications for use are based on the chemical used however most multipurpose dry chemical extinguishers are indicated for class A, B and C type fires.

- For Metal Fires: A specialist fire extinguisher for use on Class D fires – metal fires such as sodium, lithium, manganese and aluminium when in the form of swarf or turnings.

- Clean Agent – The Clean Agent Extinguisher uses both halon and halocarbon by interrupting the chemical reaction component of a fire. The extinguisher is mainly used on Class B and C fires. Larger Clean Agent extinguishers can be used on Class A, Class B, and Class C fires.

- Water Mist – The water mist extinguisher extinguishes a fire by taking away the heat element of a fire. You should mainly use this extinguisher for Class A fires but it is safe to use the water mist extinguisher for Class C fires as well.

Fire Protection

Fire protection in land-based buildings, offshore construction or onboard ships is typically achieved via all of the following:

- Passive fire protection – the installation of firewalls and fire rated floor assemblies to form fire compartments intended to limit the spread of fire, high temperatures, and smoke.

- Active fire protection – manual and automatic detection and suppression of fires, such as fire sprinkler systems and (fire alarm) systems.

Passive fire protection (PFP) in the form of compartmentalisation was developed prior to the invention of or widespread use of active fire protection (AFP), mainly in the form of automatic fire sprinkler systems. During this time, PFP was the dominant mode of protection provided in facility designs. With the widespread installation of fire sprinklers in the past 50 years, the reliance on PFP as the only approach was reduced. Lobby groups are typically divided into two camps favouring active or passive fire protection. Each camp tries to garner more business for itself through its influence in establishing or changing local and national building and fire codes.

The relatively recent inclusion of performance based or objective based codes, which have a greater emphasis on life safety than property protection, tend to support AFP initiatives, and can lead to the justification for a lesser degree of fire resistant rated construction. At times it works the other way around, as firewalls that protrude through the roof structure are used to “sub-divide” buildings such that the separated parts are of smaller area and contain smaller fire hazards, and do not necessarily require sprinklers. The decision to favour AFP versus PFP in the design of a new building may be affected by the lifecycle costs. Lifecycle costs can be shifted from capital to operational budgets and vice versa.

Fire protection within a structure is a system that relies on all of its components. The building is designed in compliance with the local building code and fire code by the architect and other consultants.

When to fight fire

It is very important to know that fighting fires is extremely dangerous and should be left to the professionals, however to minimize fire loss, some fires can be handled with minimal training if and only if an emergency plan has been implemented. A simple mnemonic to remember for an emergency plan is REACT. This mnemonic provides easy to understand rules for how to deal with fire if one is found.

- R – Remove occupants in immediate danger If this can be done without risk to yourself

- E – Ensure containment. This will confine a fire to the room of origin and prevent the spread of smoke and toxic gases. Close windows and doors if time permits

- A – Activate Alarm. This may occur automatically through alarm detection. Activate a pull station or call for help

- C – Call Fire Department Call 911 even if your alarm system calls automatically

- T – Try to extinguish If you feel comfortable using an extinguisher and the fire is not greater than your waist height.

How to use an extinguisher

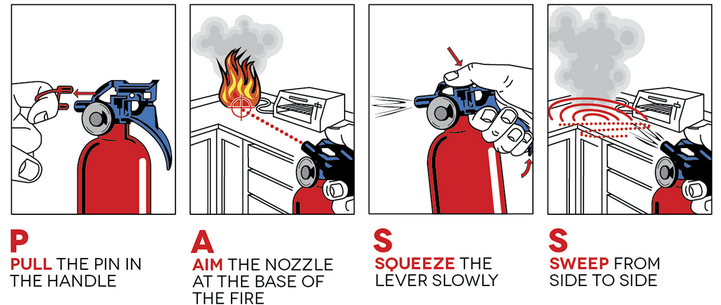

If you decide that it is safe to attempt to put out the fire yourself, then the first step is to make sure you have the right fire extinguisher for the fire. You can determine this by looking at the ULC (Underwriters Laboratories) label that is on the face of all extinguishers. Ensure that the extinguisher is the same class as the class of fire you are fighting. To remember how to use the extinguisher is as simple as the PASS procedure.

Fire Control Panels

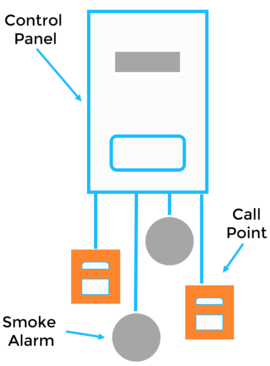

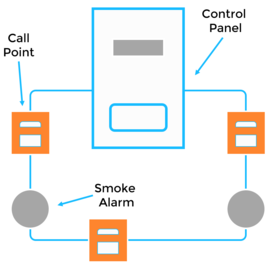

The control panel is the brain of the fire detection and alarm system. It is responsible for monitoring the various input devices such as manual call point (MCP) and automatic detection components like heat detectors, smoke detectors, and then activating alarm output devices such as horns, bells, warning lights, emergency telephone dialers, and building controls. Control panels may range from simple units with a single input and output zone, to complex computer driven systems that monitor several buildings over an entire plant. There are two main control panel arrangements, which are

Conventional Fire Control Panel – Conventional or point wire fire detection and alarm systems were for many years the standard method for providing emergency signaling. In a conventional system one or more circuits are routed through the protected space or building. Along each circuit, one or more detection devices are placed. Selection and placement of these detectors is dependent upon a variety of factors including the need for automatic or manual initiation, ambient temperature and environmental conditions, the anticipated type of fire, and the desired speed of response. One or more device types are commonly located along a circuit to address a variety of needs and concerns.

Upon fire occurrence, one or more detectors will operate. This action closes the circuit, which the fire control panel recognizes as an emergency condition. The panel will then activate one or more signaling circuits to sound building alarms and summon emergency help. The panel may also send the signal to another alarm panel so that it can be monitored from a remote point. In order to help insure that the system is functioning properly, these systems monitor the condition of each circuit by sending a small current through the wires. Should a fault occur, such as due to a wiring break, this current cannot proceed and is registered as a trouble condition. The indication is a need for service somewhere along the respective circuit.

In a conventional alarm system, all alarm initiating and signaling is accomplished by the system’s hardware which includes multiple sets of wire, various closing and opening relays, and assorted diodes. Because of this arrangement, these systems are actually monitoring and controlling circuits, and not individual devices. Assume that a building’s fire alarm system has 5 circuits, zones A through E, and that each circuit has 10 smoke detectors and 2 manual stations located in various rooms of each zone. A fire ignition in one of the rooms monitored by zone A causes a smoke detector to go into alarm. This will be reported by the fire alarm control panel as a fire in circuit or zone A. It will not indicate the specific detector type nor location within this zone. Emergency responding personnel may need to search the entire zone to determine where the device is reporting a fire. Where zones have several rooms, or concealed spaces, this response can be time consuming and wasteful of valuable response opportunity.

The advantage of conventional systems is that they are relatively simple for small to intermediate size buildings. Servicing does not require a large amount of specialized training. A disadvantage is that for large buildings, they can be expensive to install because of the extensive amounts of wire that are necessary to accurately monitor initiating devices.

Conventional systems may also be inherently labor intensive and expensive to maintain. Each detection device may require some form of operational test to verify it is in working condition. Smoke detectors must be periodically removed, cleaned, and recalibrated to prevent improper operation. With a conventional system, there is no accurate way of determining which detectors are in need of servicing. Consequently, each detector must be removed and serviced, which can be a time consuming, labor intensive, and costly endeavor. If a fault occurs, the trouble indication only states that the circuit has failed, but does not specifically state where the problem is occurring. Subsequently, technicians must survey the entire circuit to identify the problem.

Addressable Fire Control Panel – Addressable or Digital or intelligent systems represent the current state-of-the-art in fire detection and alarm technology. Unlike conventional alarm methods, these systems monitor and control the capabilities of each alarm initiating and signaling device through microprocessors and system software. In effect, each intelligent fire alarm system is a small computer overseeing and operating a series of input and output devices.

Like a conventional system, the address system consists of one or more circuits that radiate throughout the space or building. Also, like standard systems, one or more alarm initiating devices may be located along these circuits. The major difference between system types involves the way in which each device is monitored. In an addressable system, each initiating device (automatic detector, manual station, sprinkler waterflow switch, etc.) is given a specific identification or address This address is correspondingly programmed into the control panel’s memory with information such as the type of device, its location, and specific response details such as which alarm devices are to be activated.

The control panel’s microprocessor sends a constant interrogation signal over each circuit, in which each initiating device is contacted to inquire its status (normal or emergency). This active monitoring process occurs in rapid succession, providing system updates every 5 to 10 seconds.

The addressable system also monitors the condition of each circuit, identifying any faults which may occur. One of the advancements offered by these systems is their ability to specifically identify where a fault has developed. Therefore, instead of merely showing a fault along a wire, they will indicate the location of the problem. This permits faster diagnosis of the trouble, and allows a quicker repair and return to normal.

Advantages provided by addressable alarm systems include stability, enhanced maintenance, and ease of modification. Stability is achieved by the system software. If a detector recognizes a condition which could be indicative of a fire, the control panel will first attempt a quick reset. For most spurious situations such as insects, dust, or breezes, the incident will often remedy itself during this reset procedure, thereby reducing the probability of false alarm. If a genuine smoke or fire condition exists, the detector will reenter the alarm mode immediately after the reset attempt. The control panel will now regard this as a fire condition, and will enter its alarm mode.

With respect to maintenance, these systems offer several key advantages over conventional ones. First of all, they are able to monitor the status of each detector. As a detector becomes dirty, the microprocessor recognizes a decreased capability, and provides a maintenance alert. This feature, known as Sensitivity Testing, allows facilities personnel to service only those detectors that need attention, rather than requiring a labor and time consuming cleaning of all units.

Modifying these systems, such as to add or delete a detector, involves connecting or removing the respective device from the addressable circuit, and changing the appropriate memory section. This memory change is accomplished either at the panel or on a personal computer, with the information downloaded into the panel’s microprocessor.

Fire Detectors

When present, humans can be excellent fire detectors. The healthy person is able to sense multiple aspects of a fire including the heat, flames, smoke, and odors. For this reason, most fire alarm systems are designed with one or more manual alarm activation devices to be used by the person who discovers a fire. Unfortunately, a person can also be an unreliable detection method since they may not be present when a fire starts, may not raise an alarm in an effective manner, or may not be in perfect heath to recognize fire signatures. It is for this reason that a variety of automatic fire detectors have been developed. Automatic detectors are meant to imitate one or more of the human senses of touch, smell or sight. Thermal detectors are similar to our ability to identify high temperatures, smoke detectors replicate the sense of smell, and flame detectors are electronic eyes. The properly selected and installed automatic detector can be a highly reliable fire sensor.

Manual fire detection is the oldest method of detection. In the simplest form, a person yelling can provide fire warning. In buildings, however, a person’s voice may not always transmit throughout the structure. For this reason, manual alarm stations are installed. The general design philosophy is to place stations within reach along paths of escape. It is for this reason that they can usually be found near exit doors in corridors and large rooms.

The advantage of manual alarm stations is that, upon discovering the fire, they provide occupants with a readily identifiable means to activate the building fire alarm system. The alarm system can then serve in lieu of the shouting person’s voice. They are simple devices, and can be highly reliable when the building is occupied. The key disadvantage of manual stations is that they will not work when the building is unoccupied. They may also be used for malicious alarm activations. Nonetheless, they are an important component in any fire alarm system.

Thermal detectors are the oldest type of automatic detection device, having origin in the mid 1800s, with several styles still in production today. The most common units are fixed temperature devices that operate when the room reaches a predetermined temperature (usually in the 135°-165°F/57°-74°C). The second most common type of thermal sensor is the rate-of-rise detector, which identifies an abnormally fast temperature climb over a short time period. Both of these units are spot type detectors, which means that they are periodically spaced along a ceiling or high on a wall. The third detector type is the fixed temperature line type detector, which consists of two cables and an insulated sheathing that is designed to breakdown when exposed to heat. The advantage of line type over spot detection is that thermal sensing density can be increased at lower cost.

Thermal detectors are highly reliable and have good resistance to operation from nonhostile sources. They are also very easy and inexpensive to maintain. On the down side, they do not function until room temperatures have reached a substantial temperature, at which point the fire is well underway and damage is growing exponentially. Subsequently, thermal detectors are usually not permitted in life safety applications. They are also not recommended in locations where there is a desire to identify a fire before substantial flames occur, such as spaces where high value thermal sensitive contents are housed.

Smoke detectors are a much newer technology, having gained wide usage during the 1970s and 1980s in residential and life safety applications. As the name implies, these devices are designed to identify a fire while in its smoldering or early flame stages, replicating the human sense of smell. The most common smoke detectors are spot type units, that are placed along ceilings or high on walls in a manner similar to spot thermal units. They operate on either an ionization or photoelectric principle, with each type having advantages in different applications. For large open spaces such as galleries and atria, a frequently used smoke detector is a projected beam unit. This detector consists of two components, a light transmitter and a receiver, that are mounted at some distance (up to 300 ft/100m) apart. As smoke migrates between the two components, the transmitted light beam becomes obstructed and the receiver is no longer able to see the full beam intensity. This is interpreted as a smoke condition, and the alarm activation signal is transmitted to the fire alarm panel.

A third type of smoke detector, which has become widely used in extremely sensitive applications, is the air aspirating system. This device consists of two main components: a control unit that houses the detection chamber, an aspiration fan and operation circuitry; and a network of sampling tubes or pipes. Along the pipes are a series of ports that are designed to permit air to enter the tubes and be transported to the detector. Under normal conditions, the detector constantly draws an air sample into the detection chamber, via the pipe network. The sample is analyzed for the existence of smoke, and then returned to atmosphere. If smoke becomes present in the sample, it is detected and an alarm signal is transmitted to the main fire alarm control panel. Air aspirating detectors are extremely sensitive and are typically the fastest responding automatic detection method. Many high technology organizations, such as telephone companies, have standardized on aspiration systems. In cultural properties they are used for areas such as collections storage vaults and highly valuable rooms. These are also frequently used in aesthetically sensitive applications since components are often easier to conceal, when compared to other detection methods.

The key advantage of smoke detectors is their ability to identify a fire while it is still in its incipient. As such, they provide added opportunity for emergency personnel to respond and control the developing fire before severe damage occurs. They are usually the preferred detection method in life safety and high content value applications. The disadvantage of smoke detectors is that they are usually more expensive to install, when compared to thermal sensors, and are more resistant to inadvertent alarms. However, when properly selected and designed, they can be highly reliable with a very low probability of false alarm.

Flame detectors represent the third major type of automatic detection method, and imitate the human sense of sight. They are line of sight devices that operate on either an infrared, ultraviolet or combination principle. As radiant energy in the approximate 4,000 to 7,700 angstroms range occurs, as indicative of a flaming condition, their sensing equipment recognizes the fire signature and sends a signal to the fire alarm panel.

The advantage of flame detection is that it is extremely reliable in a hostile environment. They are usually used in high value energy and transportation applications where other detectors would be subject to spurious activation. Common uses include locomotive and aircraft maintenance facilities, refineries and fuel loading platforms, and mines. A disadvantage is that they can be very expensive and labor intensive to maintain. Flame detectors must be looking directly at the fire source, unlike thermal and smoke detectors which can identify migrating fire signatures. Their use in cultural properties is extremely limited.

Ionization detector is better at detecting the smaller amounts of smoke produced by flaming fires. An ionization chamber consists of two plates with a voltage across them, along with a radioactive source of ionizing radiation. Inside the ionization detector is a small amount (about 1/5000th of a gram) of Americium -241. This radioactive element has a half-life of 432 years, and is a good source of alpha particles. The principle of using a small amount of radioactive material to ionize the air between two differentially charged electrodes to sense the presence of smoke particles. Smoke Particles entering the ionization volume decrease the conductance of the air by reducing ion mobility. The reduced conductance signal is processed and used to convey an alarm condition when it meets preset criteria.

Photoelectric detector – In the normal case, the light from the light source on the left shoots straight across and misses the sensor. When smoke enters the chamber, however, the smoke particles scatter the light and some amount of light hits the sensor.

Alarm Output Devices

Upon receiving an alarm notification, the fire alarm control panel must now tell someone that an emergency is underway. This is the primary function of the alarm output aspect of a system. Occupant signaling components include various audible and visual alerting components, and are the primary alarm output devices. Bells are the most common and familiar alarm sounding device, and are appropriate for most building applications. Horns are another option, and are especially well suited to areas where a loud signal is needed such as library stacks, and architecturally sensitive buildings where devices need partial concealment. Chimes may be used where a soft alarm tone is preferred, such as health care facilities and theaters. Speakers are the fourth alarm sounding option, which sound a reproducible signal such as a recorded voice message. They are often ideally suited for large, multistory or other similar buildings where phased evacuation is preferred. Speakers also offer the added flexibility of emergency public address announcements. With respect to visual alert, there are a number of strobe and flashing light devices. Visual alerting is required in spaces where ambient noise levels are high enough to preclude hearing sounding equipment, and where hearing impaired occupants may be found.

Another key function of the output function is emergency response notification. The most common arrangement is an automatic telephone or radio signal that is communicated to a constantly staffed monitoring center. Upon receiving the alert, the control room persons will then contact the appropriate fire department, providing information about the location of alarm.

Other output functions include shutting down electrical equipment such as HVAC, computers, shutting off air handling fans to prevent smoke migration, and shutting down operations such as chemical movement through piping in the alarmed area. They may also activate fans to extract smoke, which is a common function in large atria spaces. These systems can also activate discharge of gaseous fire extinguishing systems, or reaction sprinkler systems.

The main disadvantage of addressable systems is that each system has its own unique operating characteristics. Therefore, service technicians must be trained for the respective system. Periodic update training may be necessary as new service methods are developed.

Sprinkler System

The sprinkler system consist of water storage reservoir, a pump of suitable discharge capacity and pressure, normally installed near reservoir and delivery mains taken up to the area under protection in the proper distribution of pipe mains and branches. There is an isolating valve and a special valve (known as sprinkler alarm valve) on the delivery main near the area under protection. The valve is normally under closed position due to the pressure hold at downstream of the valve by sprinkler bulbs. The pipe branches are properly distributed over the area under protection to which the sprinklers are connected.

Under fire condition the sprinkler bulb burst as the rated temperature arrives and releases the water held by glass bulb. Due to the pressure difference at the seat of alarm valve causes to open the valve to provide water to the sprinkler. As the valve get open it gives alarm with going connected to the system. The sprinklers continuously spray water at the seat of fire till the isolating valve is manually closed and reset the alarm valve.

The Sprinkler is a heat sensing device. Sprinkler Systems are of various types, temperature ranges and designs. The heat sensing element (of the Sprinkler) is pointed to the floor or to the area most prone to fire. The other end of the Sprinkler is connected to a network of pipes storing water under high pressure. Usually from 7bar to 10bar. When there is a fire, near a Sprinkler; whose temperature is higher than the temperature rated value of the, heat sensing element in the Sprinkler. The bulb present inside the Sprinkler, or the heat sensing device bursts and water now flows through the Sprinkler Systems under pressure directly on to the fire affected area. All of this is automated and happens, within 3mins, of the fire being detected. In this way Fire Protection Sprinkler System is an automatic, Fire Detection and Extinguishing System. However, Fire Sprinkler Systems was originally meant for Fire Suppression only.

Fire Sprinkler Systems are so designed to, be completely automated. This is their major advantage above all other systems. They do not require human intervention of any kind. The basic concept, is that fire will suppressed, at an infant stage. This will stop it from spreading. This is especially more advantages, if it is a residential project. As the Fire Protection System fights the fire, residents can be evacuated from the building. Hence, the chances of any person getting injured or killed because of fire, are very slim. Sprinkler System for Fire Fighting is a very effective method to suppress fire or the spread of fire.

The automatic sprinkler consists of assembly of a liquid filled glass bulb fitted in brass or bronze yoke with an deflector at outlet and threaded inlet connection. The glass bulbs are rated for particular temperature, block the outlet orifice to pressurise the downside of the alarm valve to keep valve closed in normal condition. In case of fire the liquid inside glass bulb expands and shatters the glass bulb to open the orifice and water under pressure starts flowing in the form of spray. In place of glass bulb fusible metallic string assembly is also used. Sprinklers are available in various temperature rating and selected on the basis of the temperature of the surrounding where they are to be fixed.

There are various types of fire sprinklers and below are descriptions of these so you know which one is best suited for your commercial building.

- Pre-action – Pre-action fire sprinkler systems are filled with air and water is allowed to pass through when the smoke alarm or detector goes off. This type of system requires two triggers to start water flow. It helps greatly that the pre-action fire sprinkler can be set to prevent water from spouting in case of a false alarm or a mechanical failure. The pre-action system is good for use in places where the sprinklers are only necessary when there is an actual fire so other items in the building do not get water damage from an accidental sprinkling. Such buildings include libraries and data centers. These places contain items of high value like electronics and goods damageable by water such as books

- Dry Pipe – Dry pipe sprinklers are similar to pre-action systems as they use pressurized air in the pipe which exits before water escapes. This causes a minute delay in water discharge but is ideal for buildings with low temperatures so the pipes do not freeze. These fire sprinkler systems have a fast opening tool to get rid of the air and speed up the flow of water. Warehouses located in the north are a good example of what buildings should use dry pipe sprinklers.

- Wet Pipe – Wet pipe fire sprinklers constantly have water in them. This allows for a quick reaction to a fire and is the most common type of sprinkler installed in buildings. A type of building that uses the wet pipe system is a high-rise or office building with a few floors. This fire sprinkler system is cost efficient and low maintenance.

- Deluge – These types of fire sprinkler systems also need a smoke or heat detector like the pre-action system. A deluge system has open nozzles that can be used when a hazard is present. When flammable liquids are spread across a floor, deluge fire sprinklers are good to have. In that case, buildings such as industrial parks and buildings with many tanks have deluge fire sprinkler systems installed.

Maintenance

The routine maintenance service of the system shall in general include the following as minimum requirements

- The service and maintenance work of the equipment.

- Regular monthly checks of the equipment ensuring that each items of equipment is inspected, cleaned, adjusted, greased and lubricated as required.

- Regular monthly inspection of the system and replace/repair defective parts

- Regular testing/certification of the Installation in accordance with the latest requirements and rules

- Regular annual testing, calibration and adjustment of all flow switches, level switches, pressure switches, flow regulating valves, pressure regulating valves and pressure relief valves

- Cleaning of all strainers of the F.S. pumping systems.

Fire hydrant/hose reel

- Check hydrants and hose reels for cleanliness and rectify any corrosion.

- Check and adjust the operation of all hydrants valves.

- Check hydrant can be operated manually.

- Check for any leakage.

- Check and adjust the pressure at topmost and lowest hydrants.

- Check and repair pump (including starters and controls).

- Test each hose reel and check water flow rate.

- Check and tighten that the connection of each hose reel to water pipework.

- Activate manual starter to start fire pump by breaking manual glass.

- Check and tighten wiring terminations of pump motor.

- Check air relief valves to ensure that they are in position and operative during test.

- Drain and clean all hydrant water tanks and check and report of any sign for leakage, annually.

- Check, clean and adjust ball valves and level switches as required.

- Touch up paint work as necessary.

- Check and adjust the F.S. Inlets by inserting adaptor to ensure that:-

- threads are in order,

- no leakage occurs.

Sprinkler system

- Check and rectify any leakage and damage on all sprinklers and piping.

- Check and repair any leakage of sprinkler control valves and check system water pressures.

- Check and repair water motor alarm.

- Check and repair sprinkler pumps (including starters and controls) by:-

- Manual start,

- Operation of flow switch,

- Check all wiring terminations and secure,

- Check F.S. Inlets by inserting adaptor,

- Check water tank level.

- General cleaning and greasing on moving mechanism and valves.

- Drain and clean water tank. Report any sign of leakage, on annual basis.

- Clean and adjust ball valves of water tank/adjust flow switch and level switches.

- Touch up paint work as necessary.

- Test run the sprinkler at on load condition with the power supply feed from emergency

- generators to be operated by personnel of the Employer.

Fire alarm and detection system

- Visual inspection for all manual break glass units, alarm bells and control panels are free

- from mechanical damage and corrosion and that mains connected to these point functions

- are “ON”.

- Check all fuses and D.C. batteries are in operating condition, including voltage, electrolyte

- specific gravity, etc.

- Test line between panel and F.S.D.

- Spot check not less than 10 smoke detectors and/or heat detectors functions.

- Spot check not less than 5 manual call points function.

- Check correct operation of the fire alarm and control panels and the fire control console

- (including the printer).

- Check normal operation of fire services related computerized workstation system including

- all interfacing panels.

- Check electrical main supply to control cabinet ensuring all line-supply and earth are

- correctly connected at cabinet.

- Check main supply voltage.

- Check fire alarm panel for indication on:-

- Fire under normal alarm condition,

- Fault when mains are “OFF”,

- Fault when batteries are disconnected,

- Signal to Fire Control Centre.

- Check to ensure indicating lamp of detector operates correctly.

- Check and repair the fire alarm bell on each floor by actuation of the breakglass and/or smoke detector.

- Test the signal link between individual local panels and the main fire control panels in the F.S. control room.

Portable firefighting appliances

- Check for the condition of each portable appliance (including fire extinguisher, sand bucket, fire blanket etc.) and that they are properly located.

- Check the content of the fire extinguishers and sand buckets and re-fill if necessary at extra cost to the Employer.