It is an assessment of the net profit generated by a particular product, which considers costs such as distribution, warehousing and retailing but not the original purchase price. It means of defining the actual profit achieved by a retailer of distributor from an individual product, having taken into consideration the costs of handling and storage.

The results are used in product selection, assortment planning, shelf layout planning and supply chain management.

DPP is a technique of allocating all of the appropriate costs and allowances to a given product. All distribution costs (storage, transport, etc) are therefore assigned to a specific product rather than taking an average over a whole product range. Thus, in the same way that a budgetary system operates, the actual costs of distributing a product are monitored and compared to a standard cost determined using DPP. In this way, areas of inefficiency throughout the whole logistics operation can be identified. DPP techniques can identify the costs of specific products to individual customers and so provide invaluable information for effective marketing strategies.

The benefit of DPP, being that retailers can allow for more shelf space for high turning products and reduce the amount of space for those products that move slower and yield lower profits.

DPP Goal

The goal of a Direct Product Profitability (DPP) project is to:

- Improve sales and gross margin by changing: product assortment, article presentation in the store and consumer prices

- Reduce costs by changing: process (logistics, store handling) and product characteristics (package size, item size)

DPP Formula

This metric quantifies the adjusted gross margin, less direct product costs, as

Direct product profitability (%) = Gross margin ($) – Direct product costs ($)

The basic DPP formula is:

Sales Price – Purchase Cost = Gross Margin

Warehouse Costs + Transport Costs + Store Costs = Direct Product Costs

Gross Margin – Direct Product Cost = Direct Product Profit

Why cost-to-serve analysis is important

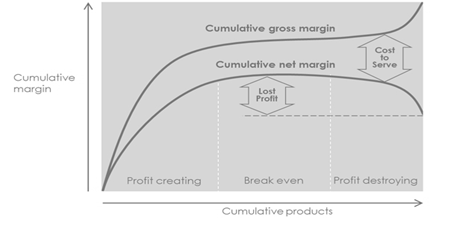

Finding better ways to conduct profitability analysis in a multi-channel world is a priority for retailers and, as a result, many are taking a second look at “cost-to-serve” analysis. This takes traditional gross margin analysis to the net margin level by analyzing all the activities and costs involved in meeting customer needs to present a view of costs and profitability by channel, customer type, store, and product group right down to individual stock keeping unit (SKU) if necessary. The diagram below shows a typical high-level report generated by such analysis.

Successfully implementing cost-to-serve analysis calls for a solution that can rapidly manipulate the large amounts of data across multiple dimensions and one that gives users the ability to quickly access and use the non-financial drivers they need when assigning costs. But in recent years, cost and profitability have been hampered by the lack of appropriate systems.

The Seven Step DPP process

The DPP model is capable of calculating net profitability of individual items of fast moving consumer goods. Working with the DPP model is a seven-step process:

- DPP model fine tuning: the classical DPP model is adapted to specific product characteristics of your industry

- Input of process characteristics: process characteristics of the logistics chain are entered as activity drivers in the DPP model (examples: delivery frequency, productivity ratios)

- Input of general ledger resource costs: resource costs of the central depot, transportation and the store (examples: transportation cost per km, costs per working hour)

- Calculation of activity costs: activity costs are calculated in the DPP model

- Input of product characteristics: all characteristics of individual products are entered as cost drivers

- Calculation of direct product costs: activity costs are allocated to products

- Calculation and presentation of direct product profitability ratios